Shalabh Chaturvedi

Managing Director, CASE Construction Equipment – India & SAARC region

What is the current market scenario of Indian construction equipment industry?

The Indian construction equipment (CE) industry is currently witnessing steady growth, boosted by a surge in infrastructure projects, urban development initiatives, and rural connectivity drives. Segments such as excavators, backhoe loaders, motor graders, and compactors are seeing heightened activity due to their critical role in infrastructure development.

Private sector involvement in real estate, industrial corridors, and renewable energy projects has further fuelled the growth of the CE market. Technological advancements, including telematics, fuel-efficient engines, and intelligent systems, are transforming the industry, with customers increasingly preferring equipment that enhances productivity and reduces operational costs. Additionally, the upcoming implementation of the BS CEV V emission standards in January 2025 is expected to drive a short-term hike in equipment sales, as customers rush to purchase before the new regulations take effect. However, the market might experience a temporary dip post-implementation, which will later stabilize.

How do you look at the Make in India initiatives in construction equipment? What are your major Make in India initiatives?

The Make in India initiative has significantly impacted the CE industry by promoting domestic manufacturing and reducing reliance on imports. At CASE, we strongly support this vision by expanding our production capacity within India and investing in state-of-the-art manufacturing facilities. From our facility in Pithampur, Madhya Pradesh, we have recently rolled out our Made-in-India skid steer loader for the domestic market, marking an important milestone in our product offerings.

A key focus for us has been on indigenizing components to reduce lead times, lower costs, and enhance supply chain resilience. By partnering with local suppliers and vendors, we not only support the Make in India initiative but also strengthen the local manufacturing ecosystem, foster innovation, and create jobs. These efforts align with our broader goal of building a self-reliant, sustainable industry in India, while delivering high-quality, durable, and efficient solutions for infrastructure development across the country.

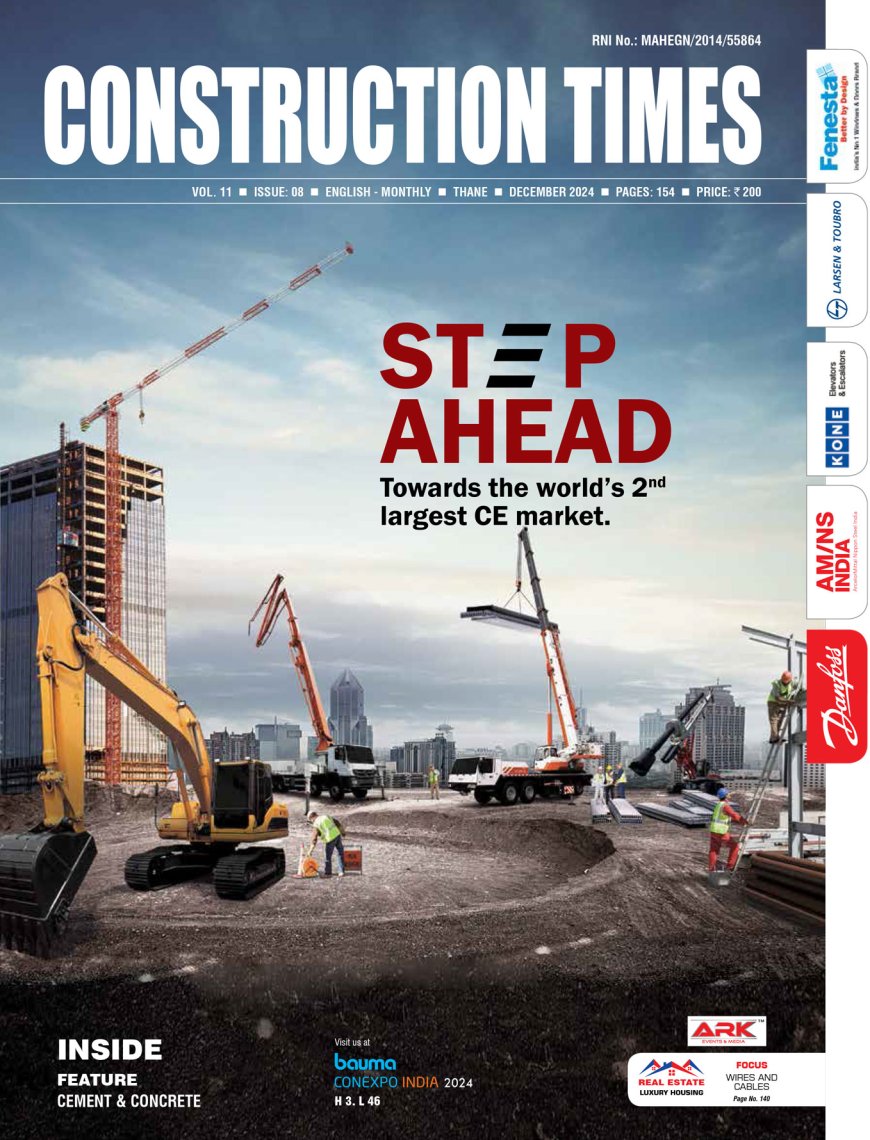

What is your vision on India becoming the second-largest CE market globally? How are you gearing up for this?

India’s rise to becoming the second-largest CE market globally is driven by rapid urbanization, large-scale infrastructure projects, and a growing focus on sustainability. CASE Construction is preparing for this growth by investing in research & development to create innovative products tailored to the Indian market. We are expanding our product offerings and leveraging advanced technologies like telematics to improve equipment efficiency and minimize downtime, ensuring our solutions meet the diverse needs of infrastructure projects across the country.

To support this growth, CASE is focusing on operator training programs and enhancing after-sales services to ensure optimal equipment usage and long-term support. Our strategy involves a balanced approach to innovation, sustainability, and expanding both domestic and international markets. By strengthening local manufacturing and indigenizing components, we aim to contribute to India’s position as a leading CE market, delivering high-quality and cost-effective solutions for infrastructure development.