Advanced simulation ensures seamless bridge installation

Installing new bridges on busy motorways is a complex, high-risk operation—even for construction companies as experienced as Skanska. When Skanska was chosen by National Highways to install two bridges as part of an improvement project on the UK's busy M42 motorway, they made use of a virtual construction rehearsal to ensure that the operation was carried out efficiently, safely, and with minimum disruption to road users.

- Marion Bouillin

Senior Product Marketing Manager at Bentley Systems

Installing new bridges on busy motorways is a complex, high-risk operation—even for construction companies as experienced as Skanska. When Skanska was chosen by National Highways to install two bridges as part of an improvement project on the UK's busy M42 motorway, they made use of a virtual construction rehearsal to ensure that the operation was carried out efficiently, safely, and with minimum disruption to road users.

Traffic congestion and poor journey reliability have constrained investment and economic growth around the M42 at junction 6. Having almost reached capacity, the junction has become a bottleneck, causing delays across the network. The situation will be exacerbated with the imminent arrival of the HS2 station at Solihull.

A multi-faceted Project

Located to the east of Birmingham, the project was highlighted in the government's 2014 Road Investment Strategy as an important junction lying in an area of dynamic growth. However, the junction did not have sufficient capacity to accommodate forecast traffic growth beyond 2019, even without the new HS2 station. The solution was to construct a new, 2.4-kilometer dual carriageway link road, aligned to the west of Bickenhill, and create a new junction on the M42 motorway, approximately 1.8 kilometers south of the existing M42 Junction 6 in Solihull. In addition, two new roundabouts north of the B4102 Solihull Road on either side of the M42 motorway and a new overbridge above the A45 near to the Arden Hotel would be constructed, providing cyclists and walkers with a safer route to cross the A45.

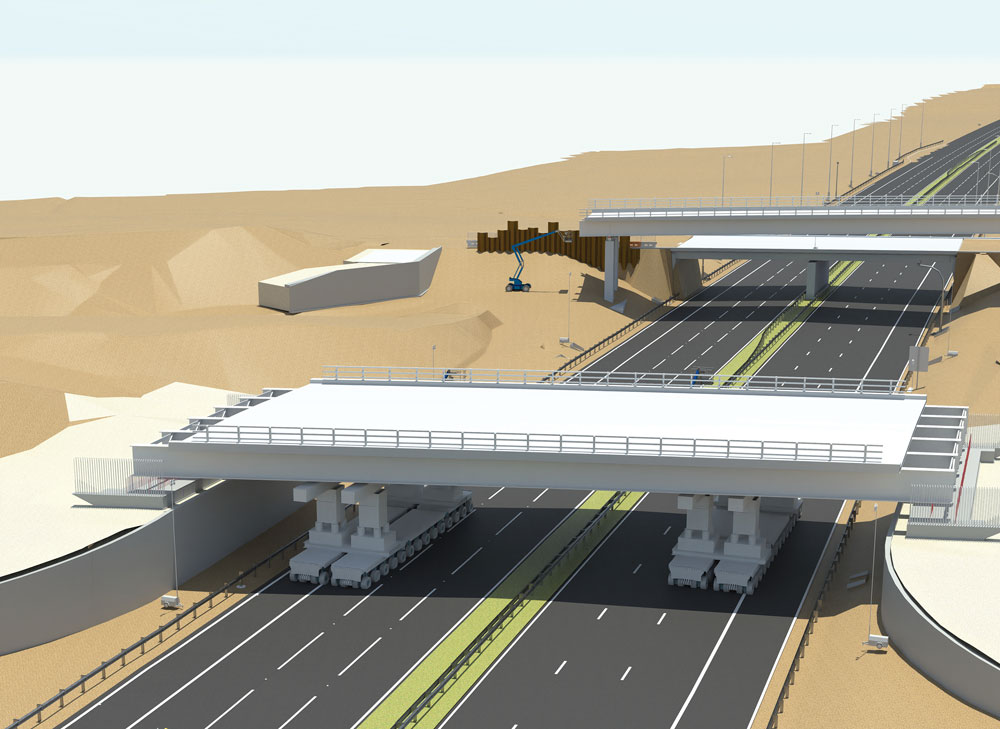

One important part of the project was to install two new bridges across the M42 motorway. In the past, bridges were constructed in position, meaning that the carriageway would need to be closed for an extended period, by leveraging self-propelled modular transporters (SPMTs), which can carry the heaviest of bridge sections, that process has been compressed. Today, engineers and contractors do not have to fabricate all sections on site. Now, bridge sections are prefabricated in one location and when all the sections are ready for installation, SPMTs are used to move them into position. This ensures minimal disruption and a safer alternative to working over a live carriageway.

Smoothing the way with simulations

To execute this highly complex operation, Skanska knew that a carefully crafted digital approach would be crucial to project success. The operation would take place over a full weekend, with the road closed from late Friday until the early hours of Monday morning. The two bridges were constructed in a field adjacent to the carriageway before being rolled into position and installed. It was crucial that the highly synchronized and complex operation proceeded without any delays in the re-opening of the road - a particularly crucial point for project stakeholders.

To ensure that the operation ran smoothly, engineers at Skanska performed digital rehearsals of the intricate operation, utilizing Bentley's SYNCHRO 4D Pro. SYNCHRO enabled the project team to digitally rehearse the construction sequence multiple times before building the asset.

The process of creating the simulation began several months prior to construction. The digital model not only included the permanent works that were being installed, but also logistics information, existing environmental conditions, and temporary works. The team collected the different 3D models of the existing environment along with the proposed environment, which was then modeled into SYNCHRO 4D. The team then started to run simulations based on the scheduled program, looking at where plant machinery was moving and assessing the overall logistics of the operation. Based on these virtual rehearsals, the program was adjusted.

“We developed the model and ran through it with all the suppliers, clients, and stakeholders, and revised the program based on that,” said Adam Steele, planning engineer at Skanska UK. “Once we had finalized our program, we sent it around to everyone so that they understood their part in the operation. We also created a video from an edited version of the simulation for public release to provide the public stakeholders with details of what we were doing and why we needed to close the road. We also used the videos for the pre-shift briefings on site. Each shift could physically see the work they were going to be doing on the shift. Finally, we used images from the video sequence in the risk assessment's method statements.”

By validating the construction plan early in a digital environment, Skanska could better refine the construction plan, while ensuring active involvement, real-time question and issue raising, and meticulous alignment of works. One of the potential problems that the simulation highlighted was that the bridge on the self-propelled modular transporters clashed with one of the CCTV cameras. That identification triggered the engineers to go onto the site and survey it in more detail. Confirming the clash, they altered the height of the bridge on the SPMTS ahead of the move rather than adjusting mid-operation.

By creating an hour-by-hour sequence of events that was visual and realistic, Skanska could better communicate what would be happening in an informative, straightforward way. This practice drove stakeholder engagement and visibility, while the customer felt aligned and upheld their trust in Skanska's works.

The development of the 4D model was a structured team effort, bringing together expertise within the project to survey existing infrastructure, develop 3D models, and build a comprehensive program that represented the work accurately. The true value of the 4D model comes from integrating operations, supply chain, customers, and designers all working as one team to create a virtual sequence of the solution.

Collaborating towards a resounding success

The project was successfully completed, as the construction simulation helped identify any significant issues. However impressive the technology, the real value comes from how it ensures that the project runs safely and smoothly.

“This is the best example I have seen of 4D animation and planning adding value to a project,” Linley said. “Not only has SYNCHRO been used successfully in a variety of planning meetings, such as the weekly readiness review, peer reviews, and various weekend closure run-throughs, but it is also now being used to brief National Highways and the different supply chain partners in the lead up to the launch weekend. What has been particularly useful is we only need to show a short video at the start of the meeting, and everyone is immediately on the same page. It has enabled efficient constructive challenge of the program without anyone needing to look at bars on a program.”

Senior Construction Engineer John Bond, a subcontractor on the scheme, commented on the power of SYNCHRO's 4D modeling: “It definitely helped me visualize and understand what will be happening for each contractor over the timeline.”

Skanska's success relied on unifying the delivery team, supply chain, and external stakeholders around a single source of project truth. Everyone could clearly understand the construction methodology and how each individual role fits into the wider operation. With SYNCHRO, Skanska was able to drive a ‘one team' approach, where all key project members could input, share, and learn around a 4D digital model, driving better decision-making and a more cohesive, transparent, and collaborative environment.

The delivery of this project will support economic growth, increase safety and reliability of the road network, increase capacity at Junction 6, and improve access to key businesses and locations.

Hits: 4