We are well-positioned to meet the growing demands of the Indian construction industry.

Er. Abinash Mishra

Chief Marketing Officer, Captain Steel India Ltd

Can you provide an overview of your company’s history and experience in manufacturing TMT bars?

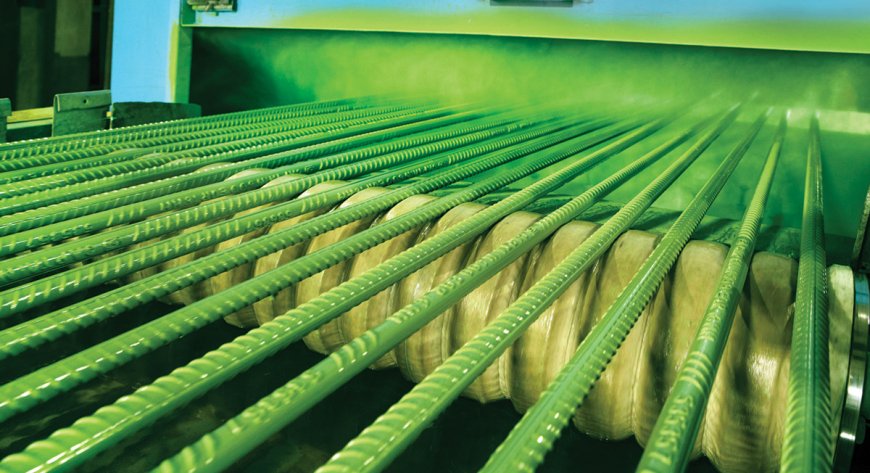

Captain Steel has established itself as a premium TMT bar manufacturer in India. Our commitment to quality and innovation is evident in every product we produce. Since our inception in 2007, we've harnessed state-of-the-art German Thermex technology to create superior quality TMT bars that meet the most stringent industry standards.

With a robust production capacity across our facilities in West Bengal and Bihar, we are well-positioned to meet the growing demands of the Indian construction industry. Our TMT bars are the cornerstone of countless durable and reliable structures across the nation.

With advancements in steel manufacturing, what are the latest innovations that have significantly improved the strength and durability of steel used in construction?

Advancements in steel manufacturing, such as Thermo-Mechanically Treated (TMT) bars, 600 EQR rebars, and Fusion Bonded Epoxy (FBE) coated rebars, have greatly enhanced the strength and durability of steel used in construction. TMT bars offer an ideal balance of strength and flexibility, making them crucial in earthquake-prone regions. The 600 EQR rebars, with their high strength and ductility, provide superior protection against seismic forces, ensuring structural safety. FBE coated rebars address the challenge of corrosion by forming a protective barrier that significantly extends the lifespan of steel in harsh environments. These innovations by Captain Steel India Limited ensure the durability, safety, and longevity of modern construction projects.

How are steel manufacturers integrating sustainable practices into their production processes to reduce environmental impact?

Steel manufacturers are increasingly integrating sustainable practices to reduce environmental impact by adopting energy-efficient technologies like electric arc furnaces (EAFs) that utilize recycled scrap steel, significantly lowering carbon emissions. They also implement waste heat recovery systems to minimize energy consumption and utilize closed-loop water recycling to reduce water usage. Additionally, manufacturers are focused on reducing waste through comprehensive recycling programs for by-products like slag. These efforts not only decrease the environmental footprint but also contribute to more sustainable and eco-friendly steel production processes.

What are the latest advancements in corrosion-resistant coatings for Steel Bars? How do these coatings enhance durability and extend the lifespan of steel structures in harsh environments?

The latest advancements in corrosion-resistant coatings for steel bars include the use of Fusion Bonded Epoxy (FBE) coatings. FBE coated rebars offer superior protection against corrosion by forming a tough, continuous barrier on the steel surface, preventing moisture, salts, and chemicals from reaching the metal. This coating is applied through a powder coating process, which ensures a uniform and durable protective layer. In harsh environments, such as coastal areas or industrial settings, FBE coated rebars significantly enhance the durability of steel structures by reducing the risk of rust and corrosion, thereby extending their lifespan and reducing maintenance costs. These coatings ensure that steel bars maintain their structural integrity and performance over time, even in the most challenging conditions.

What advancements have been made in the development of self-healing and self-repairing mechanisms for Steel Bars? How do these technologies contribute to maintaining structural strength and integrity over time?

Advancements in self-healing and self-repairing mechanisms for steel bars are still in the early stages of development and will take time to become widely adopted. One promising approach involves incorporating microcapsules containing healing agents within the steel. When damage occurs, these microcapsules break open, releasing the healing agents that react with the surrounding material to seal cracks and restore the bar’s integrity. Although this technology shows great potential for maintaining structural strength and reducing the need for repairs, it will require further research and testing before it can be fully integrated into mainstream construction practices.

In the context of smart construction materials, how are Steel Bar manufacturers leveraging nanotechnology to enhance performance characteristics such as toughness, thermal stability, and resistance to chemical degradation?

Steel bar manufacturers are exploring nanotechnology to enhance performance characteristics like toughness, thermal stability, and resistance to chemical degradation. By incorporating nanoparticles, such as carbon nanotubes, into the steel matrix, these bars can achieve superior strength and durability. Nano-coatings are also being developed to protect steel from chemical degradation. However, this technology is still in its early stages and will take time to become widely adopted in construction.

How does the integration of digital monitoring systems enhance the quality assurance and performance evaluation of Steel Bars during production, storage, and construction phases?

The integration of digital monitoring systems has revolutionized quality assurance and performance evaluation for steel bars across their entire lifecycle, from production to construction. In the production phase, real-time data from sensors ensures precise control over key parameters like temperature and composition, resulting in consistent, high-quality steel. During storage, IoT-enabled sensors monitor environmental conditions, preventing quality degradation by ensuring optimal storage conditions. In construction, RFID tags and embedded sensors track each bar’s history and monitor stress in real-time, providing valuable insights into the structural health of the building. This continuous monitoring allows for early detection of potential issues, enhancing the durability and safety of steel-reinforced structures while enabling data-driven improvements in both manufacturing and construction processes.