Ranjeet Manjarekar

Vice President - Asset Management, Tata Projects

How do you look at the current market scenario of Indian construction equipment industry?

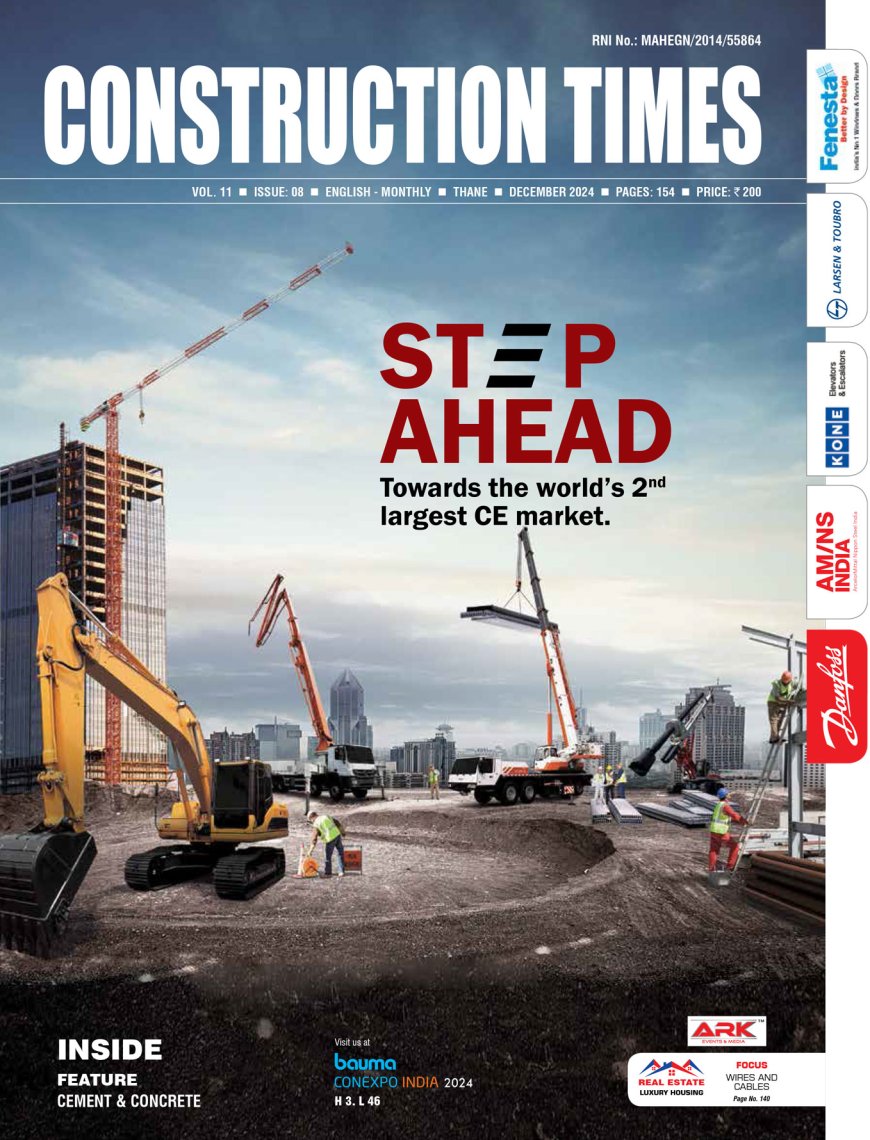

The Indian construction equipment industry is experiencing robust growth, driven by significant infrastructure development and urbanization. In 2024, the market was valued at approximately USD 7.3 billion and is projected to grow at a compound annual growth rate (CAGR) of approximately 8.5% from 2024 to 2030.

Key growth drivers include government infrastructure initiatives such as National Infrastructure Pipeline (NIP), PM Gati Shakti Master Plan, Sagarmala Project, Bharatmala Pariyojana, etc. Also, urbanization and real estate growth in terms of rising urban population, affordable housing push, and commercial and industrial real estate expansion are pushing the growth of construction equipment.

High-tech infrastructure projects such as data centres and semiconductor manufacturing find new opportunities for equipment industry. Favourable policy support such as Make in India initiative, policy reforms for accelerating infrastructure development, and increased budget allocation for infrastructure act as growth drivers of construction equipment industry.

The Indian construction equipment industry stands at an inflection point, with significant opportunities ahead. While challenges such as cost pressures and environmental compliance persist, advancements in technology, and strong demand across sectors, paint an optimistic picture for the future.

How are you sourcing plant and equipment for your construction projects?

The approach to sourcing equipment is dynamic and project-specific, balancing cost efficiency, project timelines, and operational control. Currently, we employ a hybrid model combining ownership, leasing, and subcontractor engagement to maintain flexibility while optimizing resources.

What is your view on make in India in construction equipment?

The Make in India initiative is a game-changer for the construction equipment industry. It has the potential to streamline equipment availability, reduce costs, and enhance quality standards. By fostering a robust local ecosystem, India can transition from a predominantly import-dependent market to a self-reliant manufacturing hub. Over time, this will benefit the entire construction sector by ensuring access to high-quality, affordable equipment tailored to local and global demands.

However, there are many challenges exist that need to be addressed. On technology gaps, Indian manufacturers need to continue bridging gaps in high-end equipment production, such as advanced tunnelling machines and autonomous machinery. Expanding and modernizing manufacturing facilities will help handle global-scale production. Ensuring consistent quality is imperative to compete with established global brands in premium segments.

What are your equipment fleet expansion/modernisation plans?

By increasing ownership from 18.5% to 40% over the next five years and focusing on critical categories like earthmoving, lifting, and concrete equipment, we aim to build a robust and modernized fleet. This expansion aligns with our long-term strategy to support large-scale projects, improve operational control, and achieve cost efficiencies.