SP Rajan

VP & Head – Competency Centre RBF SBG, L&T Construction

How do you look at the current market scenario of Indian construction equipment industry?

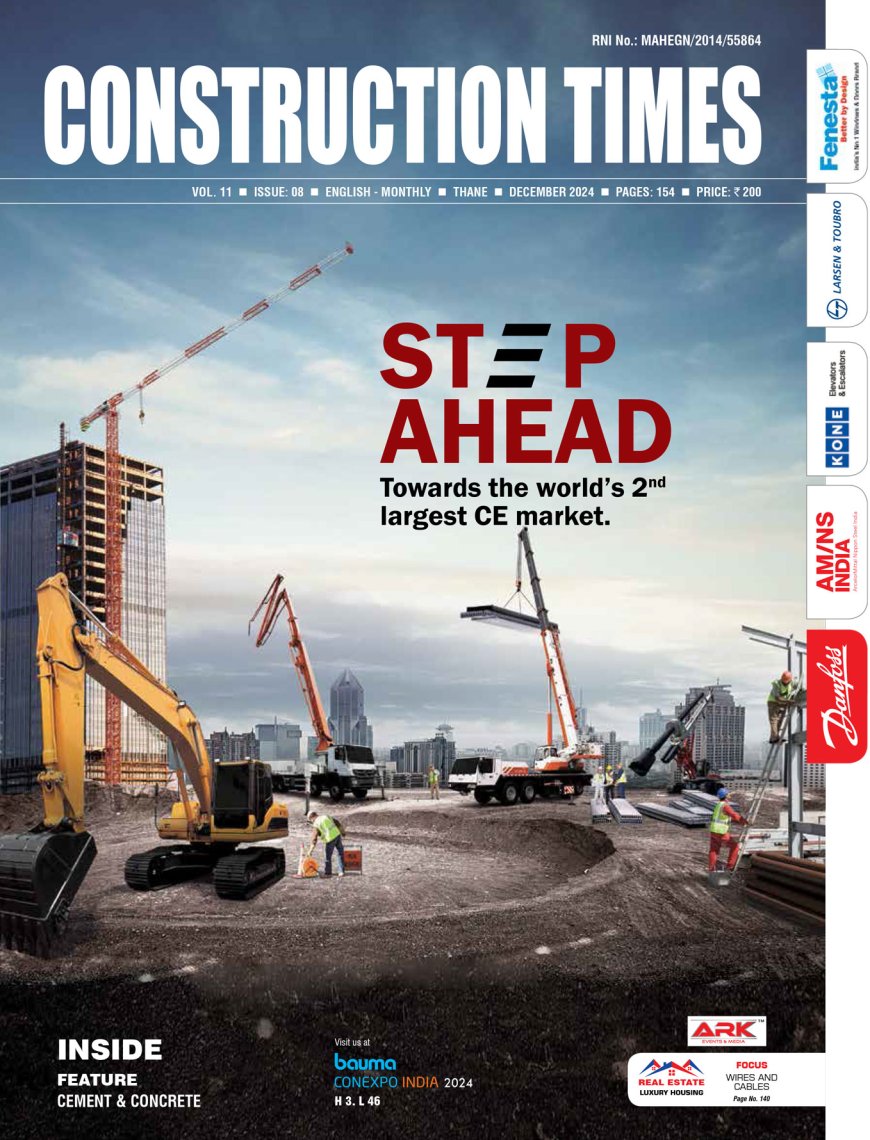

The underlying Indian growth story remains intact despite the global economy encountering volatility due to geopolitical instability, fluctuating oil prices and inflation. The government’s emphasis on infrastructure as a key driver of economic growth has played a pivotal role in this surge. Initiatives like the National Infrastructure Pipeline (NIP), which envisions investments of over $1.4 trillion by 2025, have significantly accelerated the deployment of construction equipment across various sectors like Roads, Railways, Mining, Housing, Power, Renewable Energy and New City Development.

India's construction equipment industry is projected to achieve a market size of $25 billion by 2030, reflecting robust growth driven by this substantial infrastructure development and increased government spending.

The construction equipment industry covers a wide range of machinery, including the ones for material handling, excavation, concrete production, tunneling, off shore, high-rise buildings, piling, launching etc. These are vital for the timely and efficient completion of large-scale infrastructure projects.

With the government’s push for modern and infrastructure, there is an increasing demand for technologically advanced and environmentally friendly equipment. This has led to integration of advanced technologies into construction equipment, such as automation and telematics making the machines intelligent, efficient and appealing to buyers.

The market's growth trajectory is also supported by the rising trend of urbanization and industrialization in India. As cities expand and new industrial corridors emerge, the need for construction equipment to build and maintain these developments becomes imperative.

To summarize, India's construction equipment industry is on a strong growth path, supported by government initiatives, urbanization and industrialization. Overall, the Indian construction equipment market is poised for continued growth, with an estimated CAGR of over 10-12% from 2024 to 2030.

How are you sourcing plant and equipment for your execution needs? Can you give us an update on your equipment fleet?

We own most of the equipment. Depending on the demand, we sometimes take equipment from rental agencies. More than 35,000 construction equipment (a mix of owned and hired) are in operation at any point in time. Major ones among them include cranes, batching plants, asphalt plants, WMM plants, crushers, concrete slipform pavers, asphalt pavers, motor graders, vibratory compactors, kerb casters, excavators, compressors, telehandlers, DG sets, survey kits, steel centres and many major and minor machines.

What is the share of own and rental equipment in your equipment utilisation?

Our approach to equipment utilization is strategically aligned with our project needs. We prioritize utilizing our own equipment for critical, high-stakes operations where quality, safety, and precision are paramount. This includes key infrastructure projects and strategic operations that demand rigorous standards.

For non-critical tasks, such as pick-and-carry cranes or the use of general equipment like campers, we tend to hire equipment to optimize cost efficiency and flexibility. Notably, in our large-scale, high-complexity projects such as the High-Speed Rail, L&T is deploying specialized equipment like the straddle carrier, which is not only vital for the project but is also designed and fabricated in-house by our team, showcasing our commitment to innovation and excellence in construction technology.

What is your view on Make in India in construction equipment? Will this help in streamlining equipment availability at competitive cost and quality?

India has long been a hub for engineering excellence, and with the right infrastructure, technological advancements, and skill development, the domestic manufacturing of construction equipment can play a transformative role in the sector. As of today, 45% of the equipment components are sourced from the domestic market while the rest is imported. This ratio is slowly changing with Government’s push to make India a manufacturing hub while pushing for Make in India.

From a strategic perspective, local manufacturing under Make in India can significantly streamline equipment availability. By reducing dependency on imports, we can ensure a more reliable and consistent supply chain for critical machinery, especially for large-scale infrastructure projects where timelines and quality control are key. Moreover, domestic production also addresses the specific need of Indian construction projects, which often require equipment to suit local conditions, terrain and work practices.

In terms of cost competitiveness, the ability to manufacture locally can help reduce transportation costs, import duties, and supply chain complexities, which leads to more competitive pricing. As for quality, the focus on innovation and collaboration between manufacturers and end-users will drive improvements, ensuring that the equipment is not only cost-effective but also meets international standards in terms of performance, durability, and safety.

We believe that, as more players invest in local manufacturing capabilities, it will enhance the overall competitiveness and sustainability of the construction equipment sector in India.

What are your equipment fleet expansion/modernisation plans?

At L&T, we are constantly evaluating and refining our equipment fleet to align with the evolving demands of the infrastructure sector. Our equipment fleet expansion and modernization plans are driven by the need to enhance efficiency, reduce project timelines, and maintain the highest standards of quality and safety.

Focus on technologically advanced equipment: As part of our ongoing fleet modernization strategy, we are increasingly incorporating state-of-the-art, technologically advanced machinery. This includes GPS-enabled construction equipment, autonomous vehicles, and telematics-driven solutions that allow for real-time monitoring and predictive maintenance. These innovations help to improve operational efficiency, reduce downtime, and ensure that we stay ahead of the curve in delivering large-scale projects.

Expansion of specialized equipment: For mega infrastructure projects like High-Speed Rail and other strategic ventures, we are continuously expanding our fleet of specialized equipment, such as the Straddle Carrier, which is custom-designed and indigenously fabricated in-house. We will continue to innovate and invest in more specialized, heavy-duty machinery capable of handling complex and large-scale projects with greater precision and efficiency.

Sustainability and fuel efficiency: In line with our commitment to sustainability, we are also focusing on expanding our fleet with energy-efficient equipment that adheres to the latest environmental standards. We are continuously modernizing our existing fleet to be more fuel-efficient to work towards reducing carbon emissions. These investments not only help us meet regulatory requirements but also support our sustainability goals and reduce the overall operating cost of our projects.

Expansion of owned equipment: We aim to further strengthen our core fleet by increasing the share of owned equipment. This enables us to better control project timelines and ensure the availability of critical machinery when needed, particularly for strategic operations where safety and quality cannot be compromised.

Emphasis on training and skill development: Alongside fleet expansion, we are committed to training our workforce on the latest technologies and equipment to ensure they are fully equipped to maximize the potential of the modernized fleet. This investment in human capital compliments our efforts in fleet modernization and ensures we can maintain high standards of productivity, safety and quality.