Our range of vibrators are meticulously crafted for light-duty to heavy-duty and for continuous operation.

Sundaram Iyer

Managing Director, OLI Vibrators India

How do you assess the current market scenario of Indian construction equipment industry?

Based on the data, construction industry in India is expected to see a steady growth of more than 20% YoY in view of the all-round development in the construction sector, such as cement plants, crushing plants, sand-washing plants, batching plants besides infra developments in roadways, railways, airways, waterways, ropeways, electrifications etc. This boost will certainly pave way for a steady and sustainable growth for the construction industry.

How is Make in India concept evolving in construction equipment and components manufacturing?

Can you give us an overview of your manufacturing set up and product range?

OLI Group has manufacturing set up at four places viz., Italy, Malta, Vietnam, and China. In view of the growing demand for its vibratory motors in India, the Group also has plans to set up a manufacturing facility in India by the end of 2025-26. The Group has various ranges of products that are offered to all kinds of industrial segments and more particularly, construction, infrastructure, mining-crushing-screening plants, metals, foundries, food grain processing, chemicals, enviro care, power generating plants etc.

OLI Group has manufacturing set up at four places viz., Italy, Malta, Vietnam, and China. In view of the growing demand for its vibratory motors in India, the Group also has plans to set up a manufacturing facility in India by the end of 2025-26. The Group has various ranges of products that are offered to all kinds of industrial segments and more particularly, construction, infrastructure, mining-crushing-screening plants, metals, foundries, food grain processing, chemicals, enviro care, power generating plants etc.

The products that are offered to the market specially for construction, infra, mining industries are:

• Internal high frequency vibrators of various ranges/pistol grip design and pneumatic vibrators.

• Internal high frequency vibrators with inbuilt convertors

• Shutter vibrators of various ranges for vibrating tables/moulds/battery moulds - from 3,000 rpm to 9,000 rpm.

• Fastening systems

• Excitors

• Electro-mechanical voltage convertors/electronic control panels that suits to the customer requirements

• Industrial vibrators – medium to heavy-duty ones

• Flows aids (electric and pneumatic vibrators)

The entire range of vibrators are meticulously crafted for light-duty to heavy-duty and for continuous operation. These features make OLI’s vibrators ideal for mining, construction, infrastructure industries.

How are you supporting the growth of Indian construction equipment industry through its products and solutions?

OLI Group addresses these challenges as it has the name for:

• Product quality/reliability/longevity

• Precision of the products

• Quick delivery (as it maintains huge inventory of all ranges of the products)

• Competitive pricing

• Brand OLI and its reputation in the market

• A personal and friendly touch with its customers.

• Constant R&D/technological improvements to ensure its products meet with the changing needs of the customers

• Flexible supply chain

• Specialisation and customisation of products

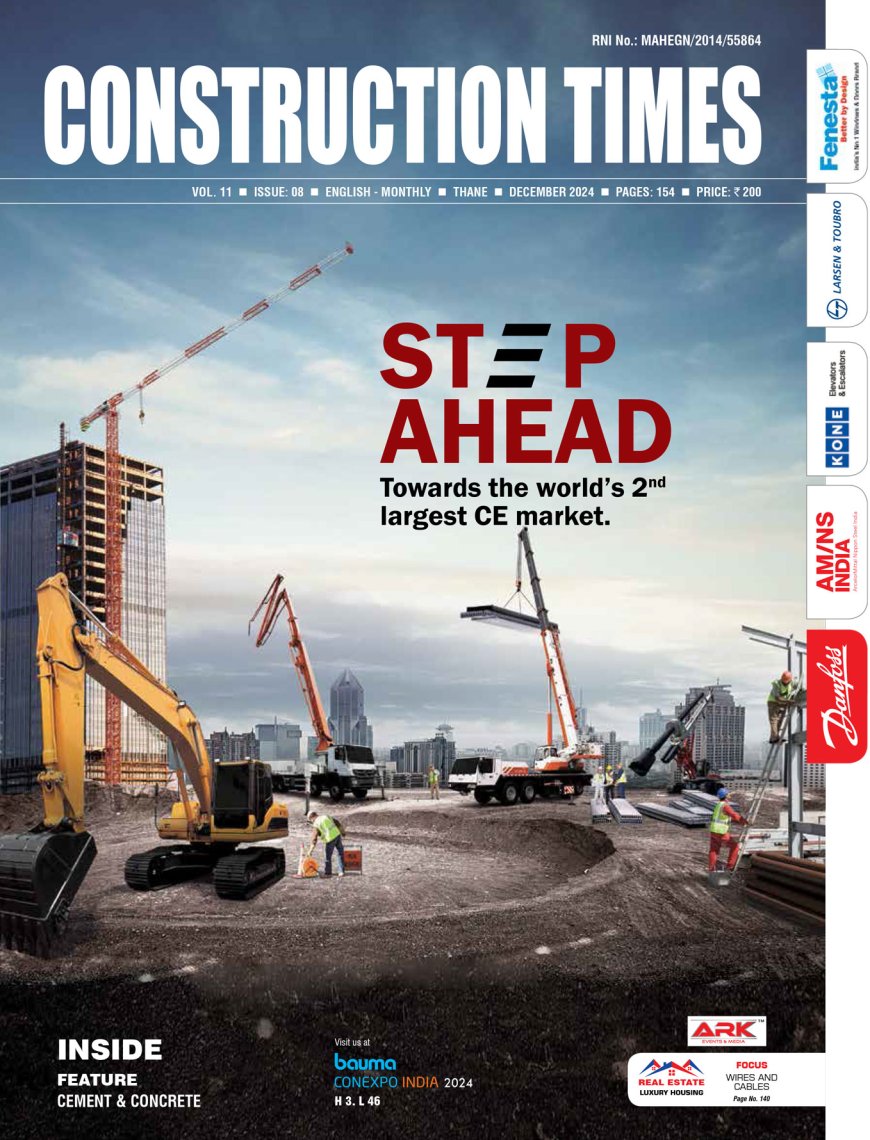

Currently India is the 3rd largest CE market globally. What is your vision on India becoming the second-largest CE market globally?

What are your expansion plans in CE components manufacturing in the coming years?

• Technological modernisations and improvements in making our products more user friendly and eco-friendly.

• To improve digital advancements in our production process to enhance operational efficiency of the products.

• Integrating contents that underscores our sustainability efforts.

• Widening our presence across Pan-India as well as globally to reach the customers and meeting their requirements.