Abhijeet Gawde

Head of Business Development & Marketing, Construction, a part of Godrej Enterprises Group

Growing urbanisation and infrastructure developments generate hazardous wastes in large quantity. How do you look at this as a threat to the environment and sustainability?

Globally, the construction sector is one of the largest consumers of natural raw materials. While it significantly contributes to urban growth, it also leads to large-scale resource extraction. Traditionally, the construction industry has followed a unidirectional path of "take-make-dispose," where resources are extracted, processed into new products, used in construction, and then disposed of as waste at the end of their functional life.

As new buildings and infrastructure projects continue to rise, the demand for building materials is expected to increase, potentially leading to acute shortages of natural raw materials. This sector faces significant challenges, including raw material supply problems and price volatility. According to the World Green Building Council, the building and construction sectors are responsible for 39% of all carbon emissions worldwide. Operational emissions, from energy used to heat, cool, and light buildings, account for 28%, while the remaining 11% comes from embodied carbon emissions associated with materials and construction processes throughout the lifecycle of buildings.

Developing countries like China and India have become major contributors of concrete debris generated from C&D waste. Developed nations like the UK, Italy, and Spain have successfully diverted waste from landfills to recycling facilities, whereas in developing countries like China, Bangladesh, and India, more than 90% of C&D debris ends up in landfills. A report by the Centre for Science and Environment (CSE) in 2020 revealed that India recycles just 1% of its Construction and Demolition (C&D) waste. It is paradoxical that while the world faces a material crisis, existing materials are being disposed of without harnessing their best value.

Recycling is the ideal way to minimise the impact of hazardous wastes. How is the company contributing to recycling of waste materials?

Effective management of C&D waste is essential for sustainable infrastructural growth globally. Most of the C&D waste comprises debris from the demolition of old buildings, roads, bridges, and other structures. C&D waste presents a resourceful opportunity, with nearly 70% of waste potentially recoverable using appropriate methods and guidelines during demolition activities. Concrete, bricks, blocks, and other fine materials form a significant portion of the overall C&D waste generated.

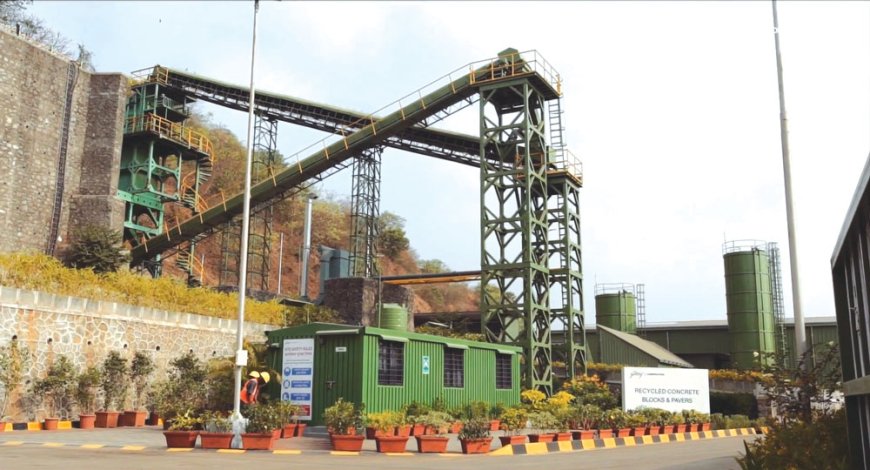

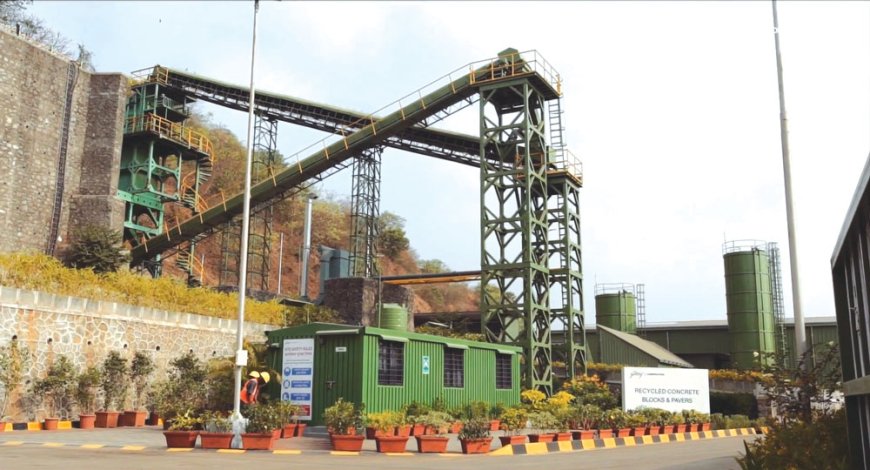

At the Construction business of Godrej Enterprises Group (GEG), we are committed to a greener tomorrow by adopting more sustainable construction practices. In line with the Circular Economy design principles, we have set up an automated Recycled Concrete Materials (RCM) manufacturing plant in Vikhroli, Mumbai. This plant manufactures a range of prefabricated concrete products using recycled concrete debris from demolished structures, which would otherwise end up in overflowing city landfills.

So far, we have recycled over 30,000 metric tonnes of concrete debris by implementing circular economy principles in our construction materials line of business. The recycled concrete debris is used for constructing customized Prefabricated Concrete Products such as box culverts, ducts, U-drains, and drain covers, customized concrete slabs, which are being utilized in major infrastructure projects in Mumbai.

We are delighted that we could be a part of the prestigious Mumbai Coastal Road project, for which we have supplied 440 large precast concrete box culverts for this project, each weighing from 30 to 35 metric tonnes. These box culverts have been used for the construction of stormwater outfall into the Arabian Sea. The box culverts have been manufactured to withstand the harsh conditions of the coastal environment, and also the heavy traffic loading conditions. With an intent to help contribute towards sustainable development, our concrete mix design has used up to 10 % recycled concrete mix in the manufacturing of these box culverts. This aspect was incorporated into the design of these concrete structures in close coordination with the project consultants.

Construction and demolition (C&D) waste creates a lot of ecological issues in the long run. What are the technologies and solutions offered in C&D waste recycling?

Our fully automated Recycled Concrete Materials (RCM) manufacturing plant in Vikhroli, Mumbai, runs on 100% Green Power and has been awarded the ‘Green Co’ Gold Certification by the IGBC. The plant is equipped with a vapour curing system, which increases the production rate by reducing the curing time and helps us deliver the finished products faster to our customers.

Can you give us an overview on how the company is using recycled materials in its projects?

From producing greener construction materials to solving the pressing issue of construction waste, we are present in every stage of the construction project development life cycle. This aligns with the Construction business of Godrej Enterprises Group’s (GEG) objective of fostering sustainable and responsible construction practices.

From producing greener construction materials to solving the pressing issue of construction waste, we are present in every stage of the construction project development life cycle. This aligns with the Construction business of Godrej Enterprises Group’s (GEG) objective of fostering sustainable and responsible construction practices.

The Godrej TUFF range of construction materials offers a breakthrough selection of customised and environmentally

conscious products. We have received the ‘Green Pro’ certificate from the Indian Green Building Council (IGBC) for the Ready-Mix Concrete (RMC) product variants of Environment Friendly Concrete, High Strength Concrete, and Self Compacting Concrete.

conscious products. We have received the ‘Green Pro’ certificate from the Indian Green Building Council (IGBC) for the Ready-Mix Concrete (RMC) product variants of Environment Friendly Concrete, High Strength Concrete, and Self Compacting Concrete.

Our TUFF walling and paving solutions include TUFF Aerated Autoclaved Concrete (AAC) blocks, TUFF– ready mix plaster, and TUFF– block binding mortar. We are happy to share that the entire TUFF walling product range is IGBC Green Pro certified. Godrej TUFF AAC Blocks are manufactured by repurposing fly ash, a by-product of coal-based power generation, helping proper disposal of fly ash to avoid contamination of groundwater and fertile agricultural land.

From producing greener construction materials to solving the pressing issue of construction waste, we are present in every stage of the construction project development life cycle. This aligns with the Construction business of Godrej Enterprises Group’s (GEG) objective of fostering sustainable and responsible construction practices.

From producing greener construction materials to solving the pressing issue of construction waste, we are present in every stage of the construction project development life cycle. This aligns with the Construction business of Godrej Enterprises Group’s (GEG) objective of fostering sustainable and responsible construction practices.

conscious products. We have received the ‘Green Pro’ certificate from the Indian Green Building Council (IGBC) for the Ready-Mix Concrete (RMC) product variants of Environment Friendly Concrete, High Strength Concrete, and Self Compacting Concrete.

conscious products. We have received the ‘Green Pro’ certificate from the Indian Green Building Council (IGBC) for the Ready-Mix Concrete (RMC) product variants of Environment Friendly Concrete, High Strength Concrete, and Self Compacting Concrete.