There will be boom in the construction activities across sectors requiring high quality TMT bars.

Lalit Beriwala

Director, Shyam Steel Industries

How do you view the market for TMT steel bars in India?

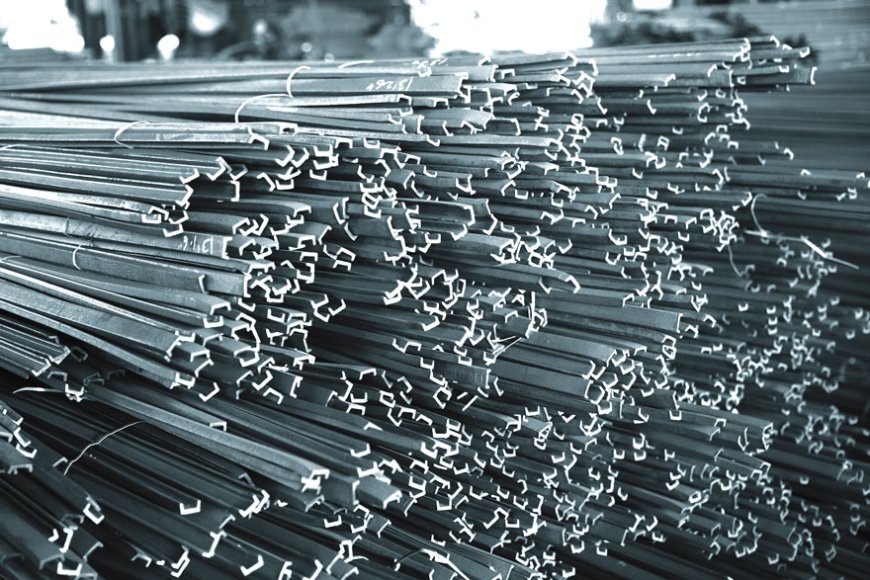

As is well known, TMT bars have come to play the most critical role in multiple areas of construction, be it building bridges, highways, metro railways, airports, atomic power stations or pipe water supply commissioning, chiefly because of their strength, ductility, seismic-pressure resistance capacity and anti-corrosive features. As per available data, the market size of the TMT bars segment was predicted to expand by 153.02 million tons between 2021 and 2026 at a CAGR of 3.50%. However, the TMT steel bars market forecast, as of now, shows a steady growth of the future market size and is expected to arrive at 9.1% CAGR by 2029, reaching US$17.3 billion.

Importantly, the TMT market is expected to register far higher (8.6% and 7.7% in 2023 and 2024 respectively, compared to global growth of 1.8 % and 1.9% respectively) growth owing to increased demand from the transportation and construction sectors in the forecast period. Available data indicate that TMT rebars’ share comes to 50-60% of India’s total steel production. In FY 2022-23, India produced a total of 128.15 million tonnes (MT) in January-November 2023 of steel share of TMT bars and rods was nearly 52 MT.

What are the specialty products offered by Shyam Steel in TMT rebars?

As of now, the range of our specialty products includes:

FlexiSTRONG: These TMT bars provide exceptional flexibility, making them ideal for use in earthquake-prone regions. Their special characteristics lie in their ability to absorb and distribute seismic forces effectively, enhancing building safety quite substantially.

Fe 600: Shyam Steel's Fe 600 TMT bars have a high yield strength of 600 N/mm² combining robustness and durability. They are specially used for construction of high rises and industrial buildings. This product induces sufficient strength to the structures.

Fe 550D: These TMT bars are the best combination of strength and ductility, suitable for critical structures like bridges and highways and are being extensively used in critical public infrastructures of national importance.

Fe 500D: Known for their superior weldability, Fe 500D TMT bars are commonly used in reinforced concrete structures. They offer excellent bond strength with concrete.

Fe 415: These TMT bars are suitable for general construction purposes. They strike a balance between strength and ductility, making them versatile for various applications.

Shyam CRS TMT: These TMT bars are ductile and corrosion-resistant, suitable for coastal areas and marine structures. They maintain their strength even in aggressive environments.

What are the key challenges faced by the TMT steel bar industry today?

It needs to be appreciated that challenges the TMT steel bar industry faces cannot be discussed in isolation. Essentially, the steel industry, as of now, faces multiple challenges which include, among others: poor logistical infrastructures, high power tariff, suboptimal transportation networks, erratic availability of railway rakes for transportation of raw materials to the works and dispatch of the finished goods to end users, volatility in the market due to unpredictable global developments, and huge demand-supply gap of critical raw materials like iron ore needed for steel industry - particularly for small and medium players. Another emerging area of concern for the TMT manufacturers lies in the development of alternatives to TMT bars for use as substitute in the construction segment. However, notwithstanding the enormity of the challenges, consumers continue and will continue to rely on TMT bars for their unchallenged supremacy in the construction sector. Besides, given the extensive use of new age technologies in the steel industry, there will be higher degree of qualitative improvement of TMT bars in terms of their strength, flexibility, corrosion-resistance quality and power of resistance against earthquake etc. That’s where the key to TMT bars’ market dominance lies.

How is the demand trend for your products and solutions in TMT rebars?

With India journeying towards Viksit Bharat aiming to transform into a developed nation by the year 2047 – set to be the third-largest economy of the world and global manufacturing hub – encompassing economic growth, social progress, environmental sustainability and good governance, there will be boom in the construction activities across sectors requiring high quality TMT bars. The trend is already visible. As already mentioned, the Central Government has laid major emphasis on infrastructural development and made provision for increased capital expenditure in the 2024-25 interim Union Budget. Such being the overall development perspective of the Government aiming to increase public spending on infrastructure building, there will be multi-prone development activities, and given the unmatched quality of Shyam Steel’s TMT bars having unassailable market penetration with proven consumers’ preference for them, it is expected that the demand for our products will register higher growth whether it is for urban rejuvenation, metro rail construction, building new airports, setting up of new power plants, building highways and jetties, warehouse or in the real estate sector. To meet the surging demand in the market and to tap newer opportunities, we are already on rapid expansion mode and are close to almost double our production capacity to 4.03 MT, post expansion.

What is your outlook on the TMT rebars market in India? What are your plans to meet the future demands?

We expect exponential growth in the TMT bar market in the coming years for the reasons I have already mentioned but what the industry needs is investment-friendly policies in terms of improved logistical facilities for hassle-free and smooth movement of raw materials to factories and finished goods to the end-users, easy availability of iron ore and other essential minerals for manufacturing TMT bars, introduction of special incentive scheme on the lines of existing PLI Scheme besides linkage of coal block and iron-ore mines for the small and medium industries who produce nearly 50% of India’s total steel production. Again, to meet the targeted production of 300 MT of steel by 2029-30 as envisaged in the National Steel Policy 2027, the much-needed policy interventions as spelt out are urgently needed.

Contextually, our company with seven decades of rich experience in the steel industry has already drawn a roadmap to make optimal use of the unfolding opportunities in the construction and allied sectors and stands committed to be a partner in India’s rapid transformation process, and to that end, we have already taken several initiatives in terms of augmenting our production capacity, digitization and upscaling of our human-power resources at different layers. We do hope that as a major steel manufacturing entity, our contribution to India’s journey towards Viksit Bharat – a journey for emerging as the third-largest economy in the world and a global manufacturing hub – will be no less significant.