In today’s world, where sustainability is crucial, Dextra is at the forefront of innovative construction solutions. By promoting the use of sea sand and seawater in concrete, Dextra not only addresses resource scarcity but also enhances the durability and resilience of structures in marine environments. However, the real breakthrough lies in the use of Glass Fibre Reinforced Polymer (GFRP) rebar, which is essential for creating reinforced concrete by solving the corrosion issue of the sea salts.

The need for sustainable solutions

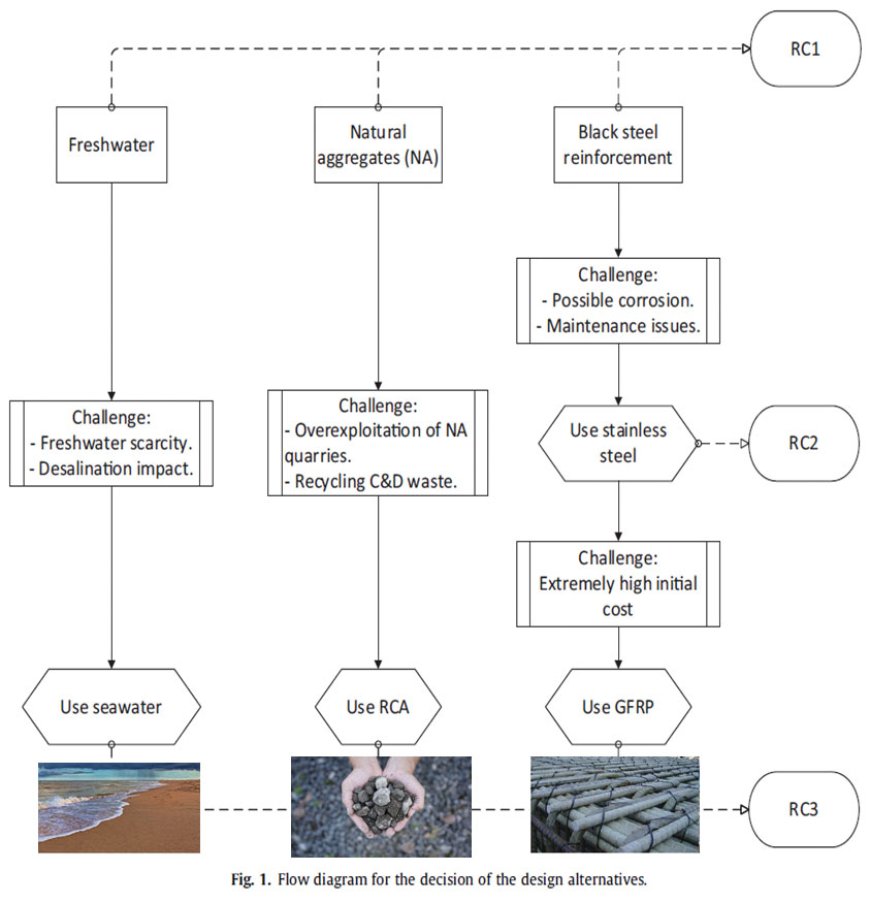

The construction and building industry are a significant contributor to greenhouse gas emissions, accounting for approximately 37% of global emissions. As water-stressed regions face increasing challenges, the use of seawater and sea sand in concrete presents a viable alternative to traditional materials. This shift not only reduces the environmental footprint of construction projects but also mitigates the rising costs associated with freshwater and river sand.

The challenge of reinforced concrete in marine applications

While the integration of sea sand and seawater into concrete is a significant advancement, the true challenge is in reinforcing this concrete effectively. Traditional steel reinforcement is prone to corrosion, especially in chloride-rich environments, which can lead to structural failures over time. GFRP rebar emerges as the keystone of this innovation, offering a sustainable and durable solution that outperforms conventional materials.

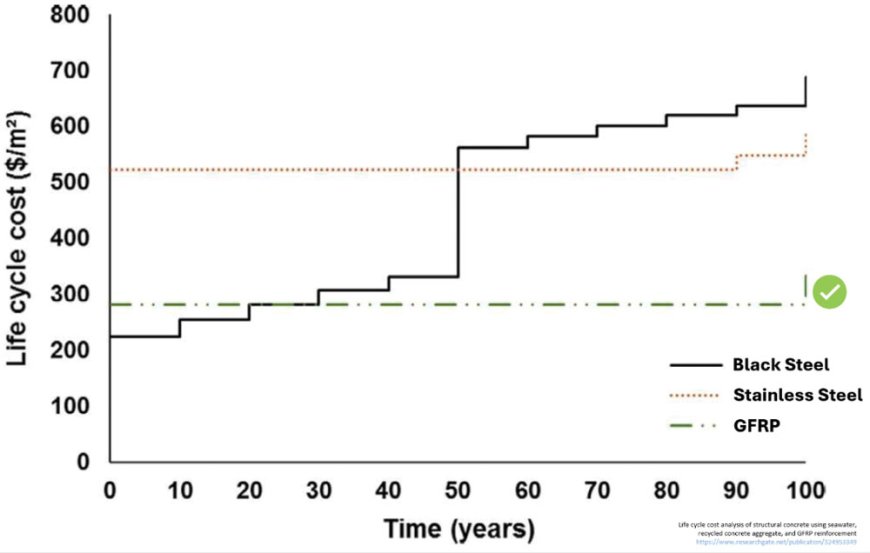

Cost-effectiveness and lifecycle benefits

Dextra’s GFRP rebar not only matches the initial construction costs of traditional methods but also provides substantial lifecycle savings. Its resistance to corrosion means lower maintenance costs and longer service life, making it a more economical choice in the long run. This is particularly important in coastal regions where the harsh environment can significantly shorten the lifespan of traditional reinforced concrete.

The key ingredient in seawater concrete is the mineral admixture (granulated blast furnace slag, fly ash, or silica fume), which, when combined with lime and seawater, undergoes a reaction to create a durable and strong material. Some chemical admixtures such as Superplasticizers can also be added to enhance the concrete properties.

Dextra has emerged as the preferred partner to provide the needed GFRP reinforcement rebars of the sea sand and seawater concrete for the most important stakeholders who want to keep their advance in this subject. Additionally, Dextra ensures the highest product standards through rigorous in-house laboratory testing and a comprehensive traceability system, which is why the Hong Kong Polytechnic University has entrusted Dextra with their GFRP rebar requirements.

Dextra has emerged as the preferred partner to provide the needed GFRP reinforcement rebars of the sea sand and seawater concrete for the most important stakeholders who want to keep their advance in this subject. Additionally, Dextra ensures the highest product standards through rigorous in-house laboratory testing and a comprehensive traceability system, which is why the Hong Kong Polytechnic University has entrusted Dextra with their GFRP rebar requirements.

Antonio Nanni, the immediate past president of the American Concrete Institute (ACI), and chair of ACI committee 243, emphasizes the importance of GFRP in modern infrastructure. He states, “The adoption of GFRP rebars is not just a trend, it’s a necessary evolution in our approach to sustainable construction. Composite reinforcement offers significant advantages over traditional black steel, particularly in environments where corrosion is a concern. GFRP can make several applications of reinforced concrete more sustainable in terms of durability, cost and environmental impact.”

Nanni notes, “I commend Dextra’s commitment to quality and innovation in GFRP manufacturing. Their products meet rigorous performance standards and provide a lightweight solution that enhances structural efficiency.” With a performance-to-weight ratio up to three times that of steel, Dextra's GFRP rebars are ideal for projects requiring both strength and sustainability.

Industry leadership

Dextra’s commitment to sustainability is further exemplified by Pierre Hofmann’s appointment to the American Concrete Institute (ACI) Committee 243 on Seawater Concrete.

His expertise will contribute to developing guidelines and standards that promote the use of seawater concrete in construction projects worldwide.

Conclusion

Dextra Group is not just a participant in the construction industry, it is a leader in sustainable practices. By embracing innovative materials like GFRP Rebar, sea sand and seawater concrete, Dextra is paving the way for a more sustainable future in construction. As research continues and new projects emerge, Dextra remains dedicated to finding better solutions that benefit both the environment and the industry.

Dextra has emerged as the preferred partner to provide the needed GFRP reinforcement rebars of the sea sand and seawater concrete for the most important stakeholders who want to keep their advance in this subject. Additionally, Dextra ensures the highest product standards through rigorous in-house laboratory testing and a comprehensive traceability system, which is why the Hong Kong Polytechnic University has entrusted Dextra with their GFRP rebar requirements.

Dextra has emerged as the preferred partner to provide the needed GFRP reinforcement rebars of the sea sand and seawater concrete for the most important stakeholders who want to keep their advance in this subject. Additionally, Dextra ensures the highest product standards through rigorous in-house laboratory testing and a comprehensive traceability system, which is why the Hong Kong Polytechnic University has entrusted Dextra with their GFRP rebar requirements.