PT Hutama Karya builds smarter, sustainable substations in Jakarta

Phase 2A of Indonesia’s Jakarta Mass Rapid Transit (MRT) expands the capital city’s mass transit in bold and exciting ways. The project extends the city’s Red Line from Bundaran HI into the old city and connects the rest of Jakarta to many cultural heritage sites. PT Hutama Karya,

Phase 2A of Indonesia’s Jakarta Mass Rapid Transit (MRT) expands the capital city’s mass transit in bold and exciting ways. The project extends the city’s Red Line from Bundaran HI into the old city and connects the rest of Jakarta to many cultural heritage sites. PT Hutama Karya, one of Indonesia’s leading state-owned construction firms, was tasked with the construction of two new underground stations: Glodok Station, spanning 240 meters, and Kota Station, spanning 411.2 meters. Both are being built at depths ranging from 17 to 36 meters below the surface. Glodok and Kota will serve as major transit hubs, transforming Jakarta’s urban landscape and connecting the MRT to nearly every corner of the city.

To complete this complex undertaking, Hutama Karya needed software that was capable of navigating the subsurface with confidence, seamlessly integrating design and construction processes, and coordinating numerous urban stakeholders to complete construction quickly and on budget.

Navigating the subsurface

Urban development projects of this scale are always challenging. They require meticulous planning and coordination between a wide range of disciplines, including civil engineers, geotechnical experts, construction teams, and city officials—all while minimizing disruption to the rest of the city. Hutama Karya wanted to interrupt urban traffic as little as possible while optimizing resource allocation. However, constructing new stations in the subsurface presents challenges that require specific data, expertise, and execution strategies to overcome.

Additionally, all these challenges were amplified by the historic nature of the build site. Both stations are being built under major roads and under or near historic buildings. As a result, there was limited land data—Hutama Karya could only execute borehole sampling at 38 points. The firm also needed to use specific soil reinforcement strategies to prevent landslides or damage to historic buildings. The company needed software that could connect design and construction workflows, maximize subsurface insights for the construction process from a limited sample size, and organize and communicate them across the various stakeholders working on the project.

Maximizing insights by capturing and integrating data

Hutama Karya decided to use subsurface, data management, and construction solutions from Bentley and Seequent, The Bentley Subsurface Company, to overcome the project’s challenges. They first used Leapfrog’s advanced soil analysis capabilities to maximize the insights available from the 38 boreholes. Hutama Karya expanded their analysis area from 3,000 square meters to 5,500 square meters, reducing geotechnical uncertainty. Next, the data from Leapfrog’s analysis was directly imported into PLAXIS, eliminating the need to remodel soil properties. With PLAXIS’ 2D model, Hutama Karya determined how to execute a top-down excavation with retaining walls supported by kingposts.

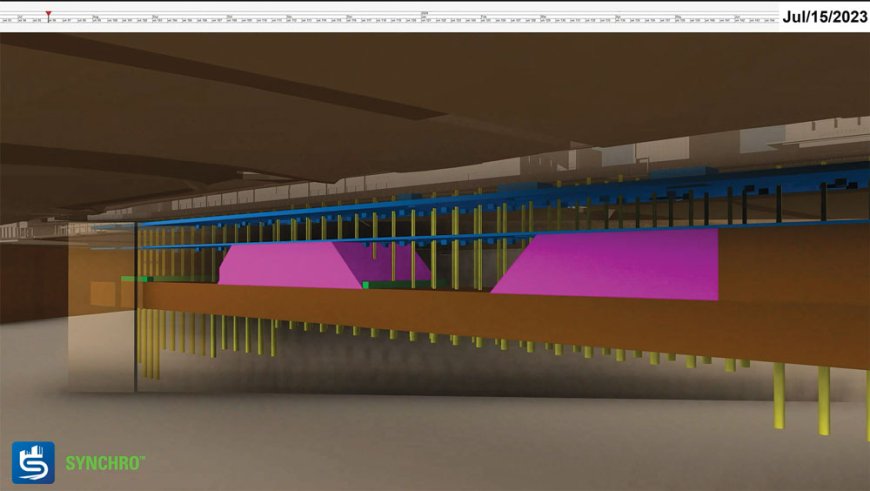

Hutama Karya then used Leapfrog data in SYNCHRO 4D, ProjectWise, and iTwin to manage the construction phase of the project cycle. Intuitive 4D models and simulations enabled better coordination and communication, which in turn enabled significant cost and time savings. As a result, they reduced the amount of heavy machinery used on site and simplified collaboration and scheduling, both within the firm and with external parties. “The precise planning and real-time insights provided by SYNCHRO 4D, iTwin, Leapfrog, and PLAXIS also ensured the protection of cultural heritage and optimized resource utilization, delivering both environmental and social benefits on a transformative scale,” said Amy Rachmadhani Widyastuti, vice president of system, IT, and information technology at Hutama Karya.

A better connected, more sustainable Jakarta

SYNCHRO 4D enabled Hutama Karya to cut rental and operational costs by 20% and lowered fuel use by 15%, amounting to a 50-ton reduction in carbon emissions. Meanwhile, ProjectWise and iTwin significantly improved project coordination and communication, offering approximately two months of time savings on large projects and slashing operational inspection efforts by 90%. By better connecting people and data, the team was able to optimize project delivery and deliver better outcomes. “Bentley software significantly propelled the Jakarta MRT Phase 2A project, seamlessly integrating over 18,000 project data points through ProjectWise,” said Amy Rachmadhani Widyastuti.

SYNCHRO 4D was used to detail work schedules, determine the excavation sequence based on soil layers, and optimize the amount of heavy machinery used. The use of excavators was reduced from 18 to 14 units and dump trucks from 20 to 17 units. SYNCHRO facilitated work control and evaluation with visualization, speeding up decision-making and evaluation.

Leapfrog has significantly improved soil data collection and analysis, reducing the time and effort needed for soil modeling and stratigraphy by up to 95%. This efficiency saves up to four weeks in planning by eliminating unnecessary data work and enhancing underground condition insights by 80%. Additionally, the models have cut excavation and retaining structure costs by 10%, preventing excavation risks and saving up to USD 2.5 million in potential damages. PLAXIS 2D also saved up to two weeks in design and improved software data exchange by 70%.

Most importantly, Jakarta MRT Phase 2A has already made a lasting impact on the city. The project has reduced carbon emissions by an estimated 25% to 35% annually by decreasing reliance on private vehicles, alleviating traffic congestion in Jakarta by 30% to 40%. Furthermore, the project's strategic use of advanced digital tools has facilitated the design and construction of energy-efficient infrastructure, leading to a 15% reduction in energy consumption across all operations. The project helps provide an improved capital for Indonesia—better connected and more environmentally friendly.

Box:

Project summary

Organization: PT Hutama Karya (Persero)

Solution: Construction

Location: Jakarta, Indonesia

Project objectives

· To build two new substation transit centers in South Jakarta.

· To reduce overall traffic congestion and carbon emissions.

Project Playbook: Bentley LumenRT, iTwin, Leapfrog, PLAXIS, ProjectWise, SYNCHRO

Fast facts:

· Jakarta Mass Rapid Transit is an ambitious project to expand public transport in the city, with phase 2A focusing on the northward expansion of the Red Line from Bundaran to Kota.

· Indonesian construction company Hutama Karya worked with Bentley to build two new substations.

· Hutama Karya used Bentley and Seequent software to analyze the subsurface, then optimize and coordinate project and construction efforts.

ROI:

· SYNCHRO 4D reduced rental and operational costs by USD 30,000 each month of the project, helping reduce carbon emissions by 50 tons.

· ProjectWise and iTwin were both used to improve project coordination, leading to a 90% reduction in time spent on operational inspections.

· Leapfrog reduced the time needed for soil modeling by up to 95%, saving up to four weeks in planning.

Image caption/courtesy 1: Hutama Karya used Bentley and Seequent software to analyze the subsurface, then optimize and coordinate construction efforts on the Jakarta Mass Rapid Transit project. Image courtesy of PT Hutama Karya (Persero).

Image caption/courtesy 2: SYNCHRO 4D reduced rental and operational costs by USD 30,000 each month of the project, helping reduce carbon emissions by 50 tons. Image courtesy of PT Hutama Karya (Persero).

Image caption/courtesy 3: ProjectWise and iTwin were both used to improve project coordination, leading to a 90% reduction in time spent on operational inspection. Image courtesy of PT Hutama Karya (Persero).

Marion Bouillin is a senior product marketing manager at Bentley Systems. She can be reached at marion.bouillin@bentley.com