A cleaner future

Aggregate demand is growing after the growing number of mega construction projects in the country. In this scenario, how are the crushing and screening equipment players gearing up? Construction Times finds out the trends.

India has fast emerged as the leading construction market worldwide. At the same time, the country’s mining sector is gaining momentum with more mining activities by using advanced technologies and equipment. In this scenario, crushing and screening equipment are evolving in the country with advanced features to match the changing needs of the customers.

Prevailing market

India has been witnessing heightened construction activities involving various mega infrastructure development plans, encompassing the development of smart cities, high-speed expressways, dedicated railway corridors, and advanced transportation systems, alongside the establishment of diverse power generation facilities including hydroelectric, thermal, and nuclear plants. The mega programmes such as Bharatmala Pariyojana and Dedicated Freight Corridor projects along with mega projects such as the high-speed rail corridor project and airport developments have paved the way for advanced high-capacity crushing and screening equipment to meet the growing needs of aggregates.

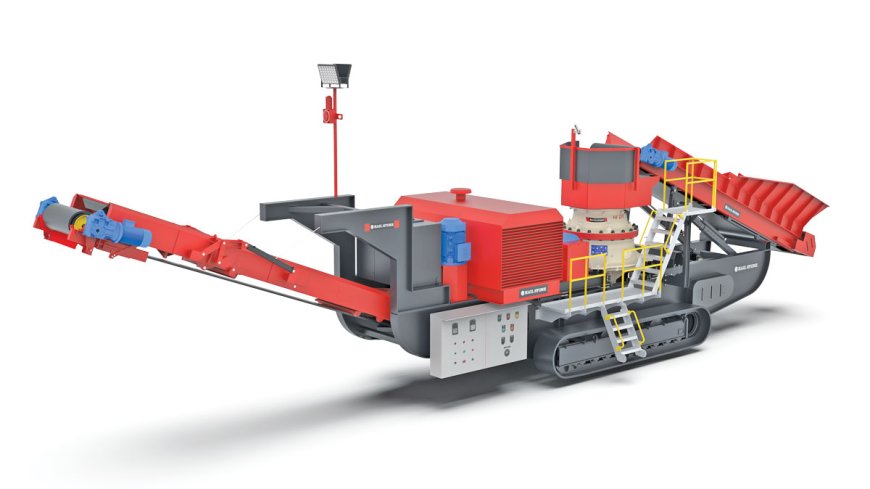

Abhijeet Pai, President, Puzzolana, elaborates, “With an impressive daily road construction rate surpassing 40 kilometers, there arises a significant demand for construction machinery, especially for plants with enhanced capacities capable of producing 300 to 500 tons per hour (TPH) of fine aggregates (-)20 mm and sand. Specifically, there is a pressing requirement for three-stage and four-stage crushing plants with capacities exceeding 300 TPH, emphasizing on the production of manufactured sand and (-)20 mm aggregate tailored for Pavement Quality Concrete (PQC) roads. In regions characterized by hilly terrain and in newly developed projects, there's a notable need for crawler-mounted crushers designed for three-stage applications (Jaw, Cone, and VSI) supplemented by screens. For railway projects, the aggregate size requirement typically ranges from 25 to 60 mm, with the remaining material comprising sand. Emphasis on quality is paramount for these ventures, necessitating plant capacities exceeding 300 TPH for a four-stage setup.”

M-sand demand

According to Pai, there is a substantial demand for high-quality M-sand, especially for applications in Zone I and Zone II. This demand arises predominantly from the construction of heavy infrastructure such as metros, bullet trains, and high-speed highways, where the use of M-sand is imperative. Consequently, M-sand is now widely incorporated into various specifications, leading to its production not only from rocks but also from alternative minerals, slag, and other sources.

Williams R J, Managing Director, Hailstone Innovations Pvt Ltd, says, “Every state is bringing out its own M-sand policy. This explains the importance M-sand is gaining now. The demand for quality M-sand is very much prevalent in the market. It is certainly a booming industry.”

Sustainable solutions in material processing

Traditionally, crushing and screening involves a lot of environmental issues mainly due to dust particles. The process of crushing & screening and transportation of the aggregates involve a lot of dust pollution and emission. Stricter regulations on mining and quarrying operations, coupled with environmental concerns, are pushing industries to adopt more environmentally friendly and sustainable equipment for material processing. The solutions offered by MB Crusher have advantages on sustainability front. Piero Guizzetti, CEO, MB Crusher India, elaborates, “Sustainability is at the core of our crushing and screening technologies, and MB Crusher have integrated various features to minimize environmental impact and promote resource efficiency. MB Crusher solutions enable on-site processing of materials, eliminating the need for transportation to off-site facilities, thereby reducing carbon emissions associated with transportation. Additionally, our machines are equipped with dust suppression systems to minimize environmental disturbance and improve worker safety. Furthermore, our technologies facilitate the production of recycled materials from construction and demolition waste, contributing to resource conservation and supporting the circular economy.”

C&D waste typically includes concrete, asphalt, wood, metals, plastics, and other materials generated from construction, renovation, and demolition activities. To address these opportunities, MB Crusher offer a range of tailored solutions. “Our bucket crusher attachments transform excavators into mobile crushing plants, enabling on-site processing of C&D waste. Additionally, we provide screening bucket attachments that separate and classify different sizes of crushed materials, allowing for the production of specific aggregate sizes required for construction projects. Furthermore, our sorting and separation attachments enable the segregation of recyclable materials from mixed C&D waste streams, enhancing recycling efficiency. Overall, our solutions aim to support the transition towards sustainable construction practices by enabling efficient and cost-effective C&D waste recycling, thus contributing to resource conservation and waste reduction,” adds Guizzetti.

Mineral beneficiation & sand washing technologies are undergoing a transformation driven by sustainability, efficiency, and innovation. Manish Bhartia, Promoter & Managing Director, CDE Asia Limited, explains the sustainable alternatives in the segment, “Concerns about water scarcity are leading to advancements in water recycling and treatment systems, allowing for reduced freshwater consumption and wastewater discharge. Additionally, modular and mobile processing plants are increasing in popularity due to their adaptability to varying production needs without extensive infrastructure. Furthermore, automation and digitalization are revolutionizing the industry by enhancing precision, efficiency, and control through real-time monitoring and predictive maintenance. Ultimately, these trends highlight a collective effort towards achieving a greener and more efficient industry that meets evolving demands while minimizing environmental impact.”

Market outlook

In India, the aggregate demand will continue to grow in future due to the large-scale construction activities across the infrastructure and real estate segments. The growing coal and iron ore mining is pushing the requirement of large capacity crushing and screening plants. Looking at these possible demand push in future, all the players are gearing up to offer advanced solutions to meet the demands. “To address the growing demand for crushed aggregates, as discussed, we are introducing larger, more productive crushers along with expanded screens and feeders to complement our existing wide array of equipment. Additionally, we are incorporating digitalization and AI technology into our offerings to further enhance efficiency and performance,” says Pai.

To meet emerging customer needs in the future, MB Crusher India has outlined several strategic plans focused on innovation, efficiency, environmental friendliness, and customer support. Guizzetti adds, “Our plans include strengthening our customer support infrastructure, expanding service networks, and offering comprehensive training programs to help customers maximize the value and performance of our equipment. Overall, MB Crusher India aims to remain responsive to emerging customer needs, drive innovation in the industry, and maintain its position as a trusted provider of sustainable and efficient crushing and screening solutions.”