Green Cement: The next frontier in ecofriendly construction

Global cement production increased at a steady compound annual growth rate (CAGR) of 4.1% to reach an estimated 4.1 billion tons in 2023 from 2.3 billion tons in 2000. While the cement industry provides a vital material for infrastructure, its production significantly impacts the environment. The cement industry's carbon footprint can be traced to its core process.

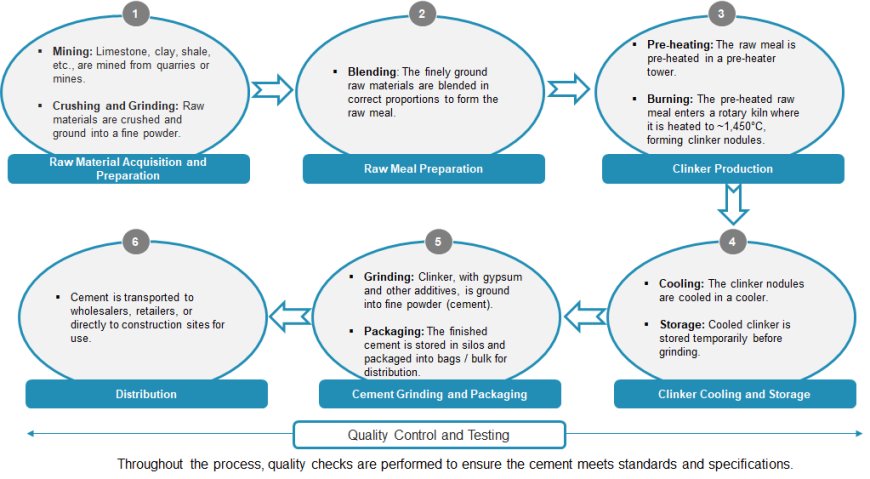

Heating limestone (calcium carbonate) in kilns to produce clinker, a key ingredient in cement, releases carbon dioxide (CO2) as a byproduct. Most cement manufacturing plants rely heavily on fossil fuels like coal for the high heat required in the kiln process. Burning these fuels releases additional CO2 into the atmosphere.

Summarized flowchart outlining key steps in cement production

For every ton of cement production, an estimated ~700 kg of CO2 is emitted. This roughly translates to around 2.9 billion tons of CO2 emissions in just 2023. Over the years, the cement industry's cumulative CO2 emissions hardly paint it as a poster child for climate resilience and sustainability. Nonetheless, stakeholders within the industry have recognized this challenge and are actively pursuing sustainable approaches to cement production.

‘Green’ cement

While conventional cement production leaves a large carbon footprint, green cement is emerging as a game changer. By utilizing carbon-negative processes and alternative materials, green cement dramatically cuts emissions.

Mentioned below are the three primary approaches for achieving greener cement production:

Minimizing required clinker – Clinker production is one of the most carbon-intensive processes in cement manufacturing. Replacing clinker with alternative materials such as fly ash or calcined clays, which emit less carbon dioxide, can lead to a reduction in the overall CO2 emissions from the cement production process.

Enhancing production process efficiency – High-efficiency grinding mills can be utilized that consume less energy while maintaining fineness requirements and have sensor-based control systems to optimize grinding parameters and minimize unnecessary grinding.

Incorporating captured carbon dioxide into end product – CO2 can be captured from the flue gases produced during cement production. The captured CO2 can be purified to remove impurities, ensuring it meets the required standards for use. CO2 can be reacted with alkaline materials, such as magnesium or calcium silicates, to produce stable carbonates. These carbonates can then be used as supplementary cementitious materials in the production of cement, reducing the need for clinker.

Performance of ‘green’ cement vis-à-vis cement from normal production

|

|

Green Cement |

Normal Cement |

|

Environmental impact |

|

|

|

Strength and durability |

|

|

|

Workability |

|

|

|

Cost |

|

|

While there can be initial cost considerations and potential workability adjustments, the long-term benefits for sustainable construction make green cement a compelling option.

As green cement technology continues to develop, production costs are expected to reduce, making it an even more attractive alternative.

Prasad Shetty,