Indian road sector: Contributions of CSIR-CRRI R&D

Roads are an integral part of a country’s transportation system. They play a major role in promoting economic and social development and also contribute to the overall performance of the society.

India has the second largest road network in the world, spanning about 66.7 lakh kilometres, which includes expressways, national highways, state highways, district roads, and rural roads. This extensive network ensures connectivity across various regions of the country. National Highways (NHs) account for only 2% of the total road network, but cater to over 40% of the total traffic.

The Government of India has been actively and generously investing in the development of road infrastructure. Major initiatives like the Bharatmala Pariyojana aim to upgrade and expand the road network, including the construction of expressways, economic corridors, and feeder routes.

The highway sector has been at the forefront of adopting new initiatives and innovations happening in the sector. Also, the adoption of the latest technology and machinery has improved the speed of the construction in this sector. Recently, National Highways Authority of India (NHAI) has created Guinness World Record by constructing 75 km continuous single lane bituminous concrete road in record time of 105 hours 33 minutes, between Amravati and Akola on NH 53 in Maharashtra. Another milestone by NHAI and Maha Metro is achieving the Guinness World Record by constructing the longest double decker viaduct (3.14 km) with Highway Flyover & Metro Rail supported on single column in between three metro stations in Nagpur.

With the massive infrastructure including roads and highways, construction activities going on in the country, it is imperative that the research and development (R&D) in the sector should also be keeping pace with the changing times and the need of the sector. CSIR-Central Road Research Institute (CSIR-CRRI) is an R&D organisation dedicated to cater to the needs of the road transportation sector.

CSIR-CRRI: The backbone of India’s road development

CSIR-Central Road Research Institute, popularly known as CSIR-CRRI, is the premier national research organization for roads, highways, traffic and transport and all other allied aspects. It carries out R&D in the area of road transportation and provides the highest level of professional consultancy to solve complex and challenging field problems faced by the executing agencies.

CSIR-CRRI was established in the year 1952 as a constituent laboratory of the Council of Scientific and Industrial Research (CSIR). The Institute is prominently located on Delhi-Mathura Road (NH-2) (New NH-44) at about 5 km from Nizamuddin Railway Station, in a huge and picturesque complex with vast and unique variety of infrastructural facilities to undertake research and consultancy activities related to roads and runways, traffic and transportation, bridges and geotechnical aspects.

As an apex organization in the road research, CSIR-CRRI has always remained in the forefront by exploring new frontal and emerging areas and providing guidance to the user departments and agencies in solving complex civil engineering technological problems. The major activities of the Institute encompass road pavement design and performance evaluation, road condition monitoring, pavement deterioration modelling, landslide management and hazard mitigation, improved transportation planning for emerging urban needs, road safety and environment issues, bridges and culverts, etc. CSIR-CRRI offers a wide range of specialised skills and technical services to the user agencies through consultancy services.

Current R&D initiatives at CSIR-CRRI

To address the current issues being faced by the road sector including scarcity of natural good quality materials, to reduce the dependency on import of bitumen and to reduce the energy consumption in the construction of roads. In this regard, several research projects have been untaken and brief details of a few of them are given in the subsequent sections.

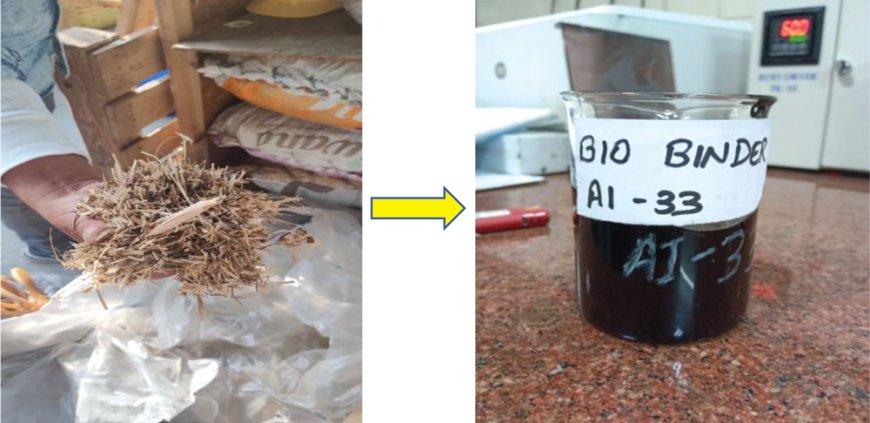

Development of bio-binder for construction of flexible pavements

The Indian bitumen market which was about 5 million tonnes in 2016 is forecasted to have an increment of 4.2% CAGR by 2024. Major supply of bitumen to India is from local market and 10% is from UAE and Iran. India imports nearly 58% of bitumen share from Iran’s bitumen market. Increased environmental regulations and usage of bitumen are the main reasons for the depletion of the non-renewable fossil resources. Due to this deficiency of petroleum products and increase in their usage, world’s oil market was forced to extract more oil products from the crude leading to lower bitumen residue production. Bitumen’s price in the market was raised globally significantly due to insufficient production. An alternative solution to overcome this issue, usage of alternative material as a replacement for bitumen will be certainly appreciated. Researchers and bitumen industry have been seeking different approaches to find out alternative material as a replacement governing the reduction in the usage of conventional petroleum bitumen. A number of alternative materials were found that could be used as bitumen replacement or rejuvenators for used recycled bitumen without any adverse effects on the environment. India is primarily an agricultural economy and also has forest cover. The presence of renewable organic carbon can be used as an alternative option to produce the crude derived fractions. The residues obtained after crop harvesting and the waste from forestry activities are a good source of lignocellulosic biomass. Lignocellulosic biomass is the most suitable option to supplement the fossil-based resources in the journey towards decarbonisation, especially for decentralised/local applications. Considering the major advantages of bio-binders and also the increased environmental issues, the current study focuses on implementing the usage of bio-oils into bituminous binder’s production. The use of bio-binders in flexible pavements is rapidly gaining interest and force within the asphalt community to substitute petroleum-based materials for asphalt mixtures. Such bio binders can act as a bitumen replacement as well as can enhance the performance characteristics of the flexible pavements under various severe climate and loading conditions.

Full Depth Reclamation (FDR) Technology

Full depth recycling (FDR) or full depth reclamation has been adopted as a road rehabilitation technique in many countries. The FDR process is employed to construct economical and long-lasting new pavements by recycling existing flexible pavements with a wide range of distresses. FDR is defined as pavement rehabilitation and up-gradation technique in which predetermined thickness bituminous and underlying pavement layers are excavated, pulverised, blended with a binder, and compacted to act as a bound or hardened base course of the new pavement. This method can be used on both distressed bituminous and granular pavements. Even though different layers of existing pavement are recycled, they are thoroughly mixed with binder and recycled to lay a single new layer of stabilised material.

Sustainable road pavements in high altitude regions using geosynthetics

The project aims towards improving performance of geosynthetic reinforced pavement layers. This study mainly deals with the roads constructed in high altitude Himalayan regions, in which pavement layers can be built using local marginal materials (like tunnel muck, landslide material, local soil) confined in geosynthetics. One indigenously developed repeated load apparatus is used to study the effect of geosynthetic confinements provided in pavement layers (at laboratory scale). Repeated load test was then used to compute the Traffic Benefit Ratio (TBR) for different cases of soil reinforcement. Using these analysed data, pavement designs were prepared for laying the field test sections. Some additional test sections have been laid in Lahaul and Spiti district of Himachal Pradesh, in addition to the previously laid test sections in Manali district of Himachal Pradesh and at Tenga Valley in Arunachal Pradesh. Performance monitoring of these field laid trial sections is underway with subsequent passage of monsoon cycles. Performed FWD on the test sections laid in Himachal Pradesh and Arunachal Pradesh in order to check their efficacy.

Development of pot-hole repair machine

CSIR-CRRI has indigenously developed a compact and low-cost pothole repair machine that uses bitumen emulsion-based mix technology. This machine is self-propelled and self-contained. The machine can carry out the cleaning and tack coating of potholes, preparation of mix in a pug mill as well as placing of bituminous mix and also compaction. The recipe of the mix is controlled automatically through PLC. The design of the machine has already been patented by CSIR-CRRI (Patent No: 400494). The technology for manufacturing this equipment has been successfully transferred to two industrial partners.

The road ahead

With the ever-evolving highways sector facing more and more challenges, new and innovative solutions/technologies need to be adopted. The sector needs to become more agile and receptive to adopt the new and innovative solutions. In some instances, such new concepts may not provide the desired output, but such failures shouldn’t be a deterrent to adopting new solutions. CSIR-CRRI is fully committed to provide practically implementable solutions for challenging problems.

|

Dr. Abhishek Mittal |