We Have A Positive Outlook On The Booming Construction And Infrastructure Segment.

Sundaram S. Iyer

Managing Director, OLI Vibrators India

How is the use of vibrators gaining pace in India with the growing construction and mining activities?

How is the use of vibrators gaining pace in India with the growing construction and mining activities?

The use of vibrators in India is still at a relatively nascent stage as compared to the developed countries. Hence one can see a steady increase in use of vibrators in Indian Industries. Secondly India’s infrastructure development spends is increasing steadily as it can be seen from the Union Budgets and state government Budgets of 2021, 2022 and 2023 and the subsequent announcements made by both the governments.

Currently, construction industry is expected to see a steady growth of more than 20% YoY in view of the all-round development in the construction sector across India viz., cement plants/crushing plants/screening plant/sand washing plants/batching plants etc., besides infra developments in airways, railways, roadways (highways & bridges), waterways, ropeways, electrification etc. These developments resulted in strong momentum in the mining industry -more particularly in metals/aggregates mining, besides river mining and sand mining.

This boosts the momentum in the construction and infra segment and in turn will certainly pave the way for a steady and sustainable growth for the vibration industry.

What are the latest products and solutions offered by OLI Vibrators?

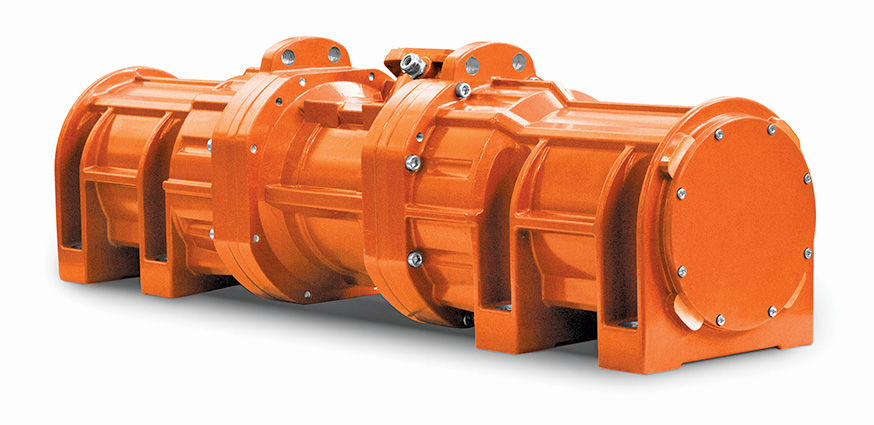

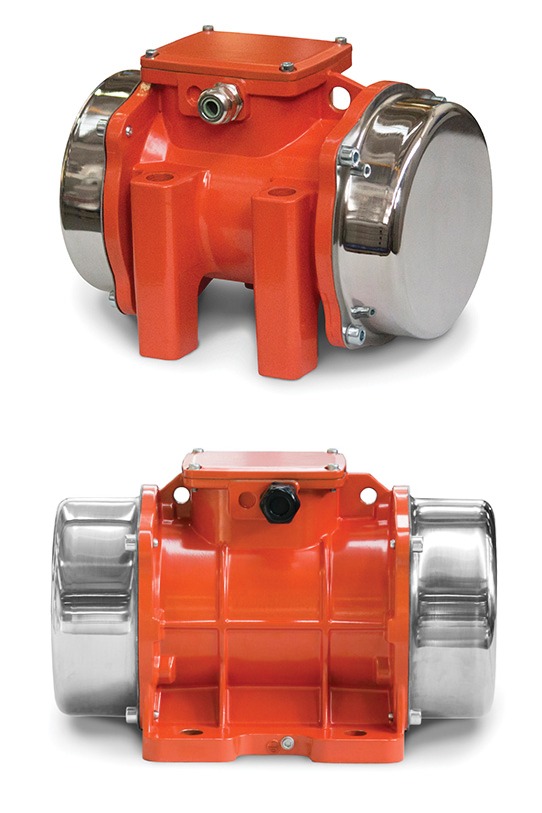

The entire range of vibro-motors is meticulously crafted for heavy duty and continuous operation. OLI’s Research & Development and Technology departments are vital in manufacturing vibro-motors tailored for the demanding construction/mining and infra industries. Our Engineering Department deserves the credit for developing vibro-motors with robust design, utilising premium quality materials like special roller bearings, life-time grease, low-loss lamination stacks and double impregnated windings.

The latest products that are offered in the market specially meant for construction/infra and mining industries are:

- Internal high-frequency vibrators of various ranges with ball-bearings and roller bearings/pistol grip design/pneumatic vibrators.

- Internal high frequency vibrators with inbuilt convertors (both ball bearing and roller bearings)

- Shutter vibrators of various ranges – for vibrating table/battery moulds – ranging from 3,000 rpm to 9,000 rpm

- Fastening systems

- Electro-mechanical voltage convertors and electronic control panels of various ranges that are suiting to the customer needs.

OLI’s electric industrial vibro-motors are designed and manufactured using the latest technologies and premium materials and components. OLI Group’s regulatory framework enables to excel in manufacturing high quality, long-lasting vibrators specially designed for mining sector carrying special characteristics like IP mechanical protection and high electrical performance. These features make OLI’s industrial vibrators ideal for mining applications, providing reliability and high efficiency.

Vibrator bodies, bearing flanges and shafts are FMEA designed and manufactured using first grade aluminium alloy, cast iron and steel alloy to withstand heavy duty applications that guarantee safe operation in any condition.

How are you meeting the growing needs of customers in a time-bound and cost-effective way?

The biggest challenge currently for India as well as globally is ensuring high quality of vibrators are manufactured (both electric and pneumatic vibrators) and maintaining the consistency of that quality in the context of vibro-motor industry.

OLI Group has a wide geographical spread globally through its 25 plus wholly-owned subsidiaries across the world carrying a large inventory to cater to local and global markets.

OLI stands for product quality, precision, competitive pricing, quick delivery, and user-friendliness. These features differentiate OLI from its competitors.

OLI’s slogan is ‘WHEN YOU NEED – WHERE YOU NEED’, which symbolises that OLI stocks material and ensures that deliveries are done ON TIME to the customer.

OLI has done more than a decade’s research and evolved a framework for quality on two strong pillars viz., best practices and strong QAP procedures. OLI is always on the quest for exploring new grounds and long-lasting solutions by understanding and serving the needs of the customers.

OLI has a very strong focus on the capabilities needed to succeed in the changing market needs. This helps OLI in meeting up the challenges and demands and advancing the technologies to align with the fast-changing industry needs.

What are your plans for this year to attract customers?

Excon provides a good opportunity for the construction/material handling equipment, especially vibrators and other accessories manufacturers to interact with our customers on one platform. Over the years, Excon has grown considerably in size as well as stature.

Excon provides a good platform for the industry to showcase the best technology in the construction/infra space. Excon acts not only as an ideal launch pad for newer products but also as a breeding ground for newer concepts and ideas. We expect that this edition of Excon will continue this contribution to the industry with more ideas being generated and more visitor footfall.

How are your technologies and services going to address the changing needs of the customers?

How are your technologies and services going to address the changing needs of the customers?

OLI’s quality policy ensures that all products pass through stringent quality/test procedures ensuring no compromise on quality of the product and usage of high quality raw-materials and components (such as optimised grease sealing systems and certifications from international bodies such as ATEX/IECex/ETL etc.

Reputation of OLI Group and its brand ‘OLI’ has been recognised with WORLD LEADER status for many years in the vibration industry.

OLI SpA emphasises and practises flexible supply chain. This contributes to our ability to adapt swiftly to market changes and maintain a competitive edge.

OLI showcases its commitment to ‘Specialisation’. This dedication, positions OLI at the TOP in the vibration industry.

Our state-of-the-art vibration technology & innovative programs and cutting-edge R&D initiatives exhibit our continuous pursuit of innovation we show case. This helps us in building confidence in facing any challenges and complex situations.

A personal touch and interaction by the OLI team are uniqueness of OLI products reaching wider markets inter-alia including niche markets.

What are your future expansion plans and market outlook?

What are your future expansion plans and market outlook?

The long-term prospect for India continues to be quite promising. We have a very positive outlook on the booming construction and infrastructure segment, and we envisage a rapid growth in the next 5-6 years. Large scale projects by the central and state governments in sectors including roads, inland waterways, ports, airports and infrastructure modernisation in the urban cities and Tier-1 and Tier 2 are on the rise.

To meet with the growing market, we are preparing ourselves in meeting up the challenges be evolving the following:

- Integrating content that underscores our sustainability efforts, demonstrating our responsibility and accountability towards environmental stewardship.

- Digitalisation – OLI Group harnesses digital advancements in its production processes to enhance operational efficiency and stay at the forefront of technological advancements.

- Technological modernisation and improvements in making the products more user friendly.

- Widening our presence across pan-India and globally to reach the customers and meeting their requirements.