Implementation of tunnel safety protocol should be strictly followed

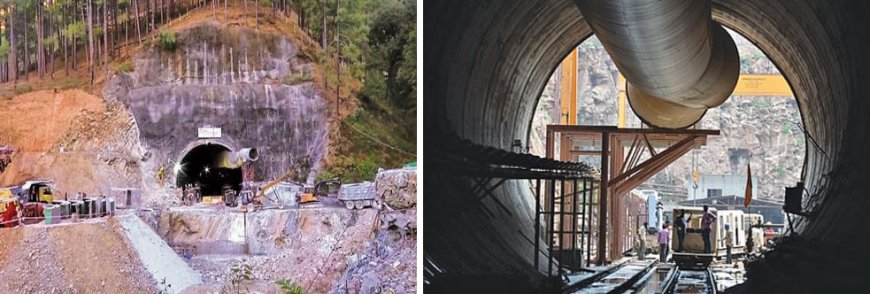

Tunnelling has now become an integral part of our infrastructure development, particularly in transportation and hydropower projects. With increased investment in road and railway tunnels, as well as metro and urban underground spaces, the total length of tunnels in India has seen substantial growth.

How do you view the current scenario of tunnelling in India? What is the total length of tunnels?

Tunnelling has now become an integral part of our infrastructure development, particularly in transportation and hydropower projects. With increased investment in road and railway tunnels, as well as metro and urban underground spaces, the total length of tunnels in India has seen substantial growth. Currently, India has over 2,500 km of tunnels constructed or under development, covering national highways, railway corridors, metro and hydropower systems.

How is the development of road and railway tunnel projects progressing in the country?

Road and railway tunnel projects improve connectivity in difficult terrains, such as the Himalayas and the Western Ghats. Four-lane projects have given a strong push to road tunnels, while the Dedicated Freight Corridors (DFCs) and high-speed rail corridors are driving railway tunnelling which is being planned based on detailed techno-economic data. Notable projects include the Chanani Nashri, Atal, Z-mor and tunnel completed on Jammu to Srinagar section rail project.

How are underground and mountain tunnel projects helping in creating better connectivity infrastructure?

Underground and mountain tunnels are crucial for reducing travel time, improving safety, and enhancing economic activity. These tunnels help bypass difficult terrains, provide access to remote regions, and facilitate urban decongestion through metro and road tunnels. For instance, tunnels in Jammu & Kashmir and the Northeast are transforming regional connectivity, boosting tourism, and enabling economic growth.

How is technology evolving in tunnelling? How are technologies such as TBMs making tunnelling safer and sustainable?

Technology in tunnelling has advanced significantly, making construction faster, safer, and more sustainable. The use of Tunnel Boring Machines (TBMs) has improved excavation efficiency while reducing environmental impact. New ground improvement techniques, digital monitoring, and AI-based predictive analysis are enhancing safety and project execution. The adoption of prefabricated tunnel lining segments and sustainable materials is also ensuring longevity and reducing carbon footprints. Safety during construction and operation of tunnel is a priority. We advocate for advanced safety protocols, including remote monitoring systems, predictive modelling and real-time ventilation control, enhanced training for workers, especially in confined space safety. Innovations such as IoT-based sensors to monitor structural integrity, automated early-warning systems, and worker-tracking devices have been crucial in reducing incidents. Encouraging a safety-first culture

priorities. Notwithstanding this there is need that each worker in tunnel industry be educated about safety and should be completely trained to handle any untoward incident. Implementation of tunnel safety protocol should be strictly followed and lapse should not be acceptable.

The recent incidence in Telangana SLBC tunnel is a wakening call for safety concern for us even working with TBM for long tunnel.

What are the major challenges encountered in tunnelling? How are you minimizing the challenges?

Tunnelling in India faces challenges such as complex geological conditions, high seismic activity, water ingress, and difficult accessibility. To address these, we employ geo-physical method, geological investigations, advanced ground support systems, and innovative excavation techniques. Modern grouting methods, real-time monitoring, and tunnel ventilation systems are also used to enhance stability and worker safety.

How is the association taking steps to strengthen and streamline the tunnelling activities in India?

The Tunnelling Association of India (TAI) is playing a key role in knowledge dissemination, skill development, and policy advocacy. We regularly organize conferences, technical workshops, and training programs to upgrade industry standards. Additionally, we are working closely with government bodies to streamline regulations and promote the adoption of advanced tunnelling practices. Expert registration has been started by the association to enhance capacity building. Review of DPRs by experts’ groups has been strongly recommended as such review can be of great help in tunnel proposals, especially to address risk assessment in advance and for ensuring safety plan during construction. Important institutes in the country have been requested to share ongoing research on tunnels, for optimization of cost of tunnel construction and for updating various guidelines.

What is your outlook on the growth of tunnelling in the coming years?

The tunnelling sector in India is poised for significant growth, driven by the increasing demand for efficient transportation networks, urban expansion and water infrastructure projects. With initiatives like the Gati Shakti National Master Plan and rising private sector participation, we expect tunnelling activities to expand rapidly. The use of digitalization, automation, and sustainable construction techniques will further shape the future of tunnelling. Government policies heavily influence project timelines, costs, and environmental considerations in tunnelling. Keeping in view of potential of tunnel work in India, we should have a Centre for Tunnelling for overall development of all types of tunnels with a special focus of safety protocols using different methodologies of tunnel construction. Considering the huge potential for tunnel works ahead, a proposal for early installation of TBM factory along with rich support system to reduce downtime of procurement from overseas, need to be explored in the country.