We are helping shape the next generation of intelligent transport in India.

The Indian railways & metro segment is currently witnessing a robust growth trajectory, driven by strong government focus, increased infrastructure spending, and a clear shift towards sustainable transportation.

How do you view the current market trend in the railways and metro sector in India?

The Indian railways & metro segment is currently witnessing a robust growth trajectory, driven by strong government focus, increased infrastructure spending, and a clear shift towards sustainable transportation. The railways, in particular, is experiencing significant momentum driven by large-scale electrification initiatives, modernization of existing assets, and the transition from diesel to electric traction. As of early 2025, Indian Railways has electrified over 90% of its broad-gauge network, with a target of achieving full electrification in the near future, creating substantial demand for electric trains and high-efficiency locomotives.

Simultaneously, the urban mobility landscape is undergoing a transformative shift. India’s metro rail network, which stood at about 850 km in 2023, is expected to cross 1,200 km by 2026 with new lines being added in emerging cities like Pune, Thane, Patna, Bhubaneswar, and the ongoing expansions in Mumbai and Delhi. This expansion presents a clear opportunity for advanced traction technologies that support efficient, low-emission, and reliable rail operations.

At ABB India, we see this as a crucial time for the traction industry. The demand is not just for volume but also for innovative solutions that offer energy efficiency, smart diagnostics, and longer lifecycle performance. Our traction offerings are designed to align with this market need, supporting both mainline railways and metro systems in their journey towards electrification and modernization.

India’s railway sector is on a modernisation mode. How is the company contributing to railway modernization?

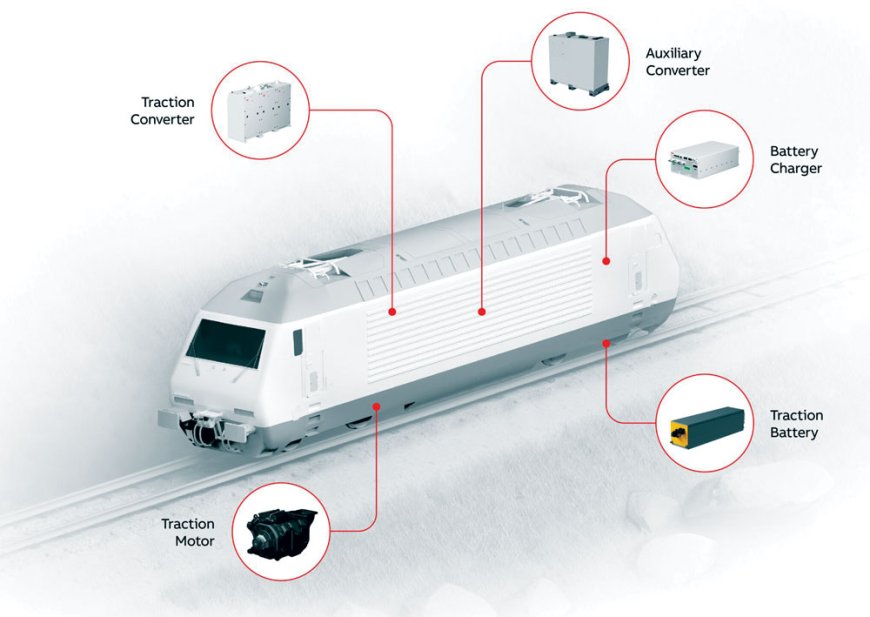

At the heart of our contribution is our ability to localize cutting-edge technology for Indian conditions. With world-class manufacturing facilities in Vadodara and Bengaluru, ABB India supplies a wide portfolio of traction converters, auxiliary converters, and traction motors for Electric Multiple Units (EMUs), electric locomotives, and metro systems. These products are engineered to deliver high energy efficiency, reduced maintenance needs, and superior reliability, key factors for the future of India’s high-utilization rail network.

A recent milestone is the successful development and deployment of India’s first locally manufactured silicon carbide (SiC)-based battery chargers for rail applications. SiC technology plays a crucial role in reducing energy consumption and enabling regenerative braking systems, directly contributing to Indian Railways' goal of becoming a net-zero carbon emitter by 2030.

A recent milestone is the successful development and deployment of India’s first locally manufactured silicon carbide (SiC)-based battery chargers for rail applications. SiC technology plays a crucial role in reducing energy consumption and enabling regenerative braking systems, directly contributing to Indian Railways' goal of becoming a net-zero carbon emitter by 2030.

ABB’s solutions are also future-ready and digitally enabled, supporting predictive maintenance and fleet performance optimization. Our efforts are not limited to supplying hardware but also involve close collaboration with key OEMs, Indian Railways, and metro corporations to co-develop customized solutions that meet the demands of rapid urbanization and increasing passenger volumes.

How are the company’s automation and control solutions transforming railway operations and services?

As India’s rail network modernizes at scale, automation is becoming the backbone of smarter and more resilient operations and ABB is at the forefront of this evolution. A key example is our Train Control and Management System (TCMS), which serves as the digital brain of modern rolling stock. This system is deployed across various Electric Multiple Units (EMUs) and India’s flagship trains, including the Vande Bharat Express. The TCMS continuously monitors and manages multiple on-board systems such as traction, braking, HVAC, doors, and passenger information in real-time, ensuring seamless coordination, optimal performance, and enhanced safety.

Designed for high reliability and energy efficiency, ABB’s automation systems not only improve uptime and operational availability but also enable predictive maintenance by providing real-time diagnostics and analytics. Our intelligent control systems are engineered to reduce energy consumption and support regenerative braking, contributing directly to energy conservation and emissions reduction across the network. By integrating robust control platforms with cutting-edge digital technologies, ABB is not just helping railways move people and goods more efficiently; we’re helping shape the next generation of intelligent transport in India.

How do you look at the advancements in the metro rail segment? What are the innovations from the company for metro services?

We are contributing to the next phase of metro modernization through our state-of-the-art traction converters specifically engineered for metro applications. Our latest generation of converters offers up to 20% energy loss compared to traditional systems, significantly improving the overall energy efficiency of train operations. These systems are compact, lightweight, and designed for India’s demanding operating environments, supporting smoother acceleration, regenerative braking, and higher reliability.

Beyond traction, ABB is also enabling smarter metro services through digitally integrated automation and control solutions that enhance train performance, safety, and uptime. These innovations ensure that metros can run leaner and cleaner perfectly aligning with India’s urban sustainability goals and the broader vision of net-zero emissions. As customers increasingly seek solutions that are not only robust and cost-effective but also future-ready, ABB’s locally manufactured and globally benchmarked technologies provide a strategic advantage.

Railways still has a long way to go in expansion and modernisation of its services and facilities. How do you look at this as an opportunity for your solutions?

With the government’s sustained focus on infrastructure development, decarbonization, and ‘Self Reliant India’, the modernization of railway services and facilities offers a vast canvas of opportunity for advanced, technology-driven solutions. ABB views this as a strategic growth avenue both in supporting greenfield developments and in upgrading existing systems to meet modern performance and sustainability standards.

Indian Railways, one of the world’s largest and most complex networks, serves over 23 million passengers and 3 million tonnes of freight daily. While much of the infrastructure still relies on legacy systems, the sector is rapidly advancing toward 100% electrification, net-zero carbon emissions by 2030, and high-speed corridors.

ABB’s traction portfolio is well-positioned to support this transformation. We offer a locally manufactured range of traction converters, auxiliary converters, battery chargers, and energy-efficient onboard systems that are engineered for durability, energy optimization, and integration with both new and aging fleets. Our modular, compact solutions are ideal for retrofitting older rolling stock, with innovations like silicon carbide-based battery chargers that reduce energy use and improve thermal efficiency, a key to successful modernization.

What are your future plans in the modernisation and expansion of railways and metro systems and services?

Our future roadmap focuses on bringing next-generation traction technologies to the Indian market, solutions that are not only globally benchmarked but also engineered specifically for Indian operating conditions. This includes the upcoming launch of advanced roof-mounted converters, designed for space optimization and modular integration into metro and EMU fleets. These systems will offer higher energy efficiency, simplified maintenance, and improved reliability in the often harsh and high-temperature environments.

We’re also introducing high-efficiency 3-level inverters, which significantly reduce harmonics and energy losses while improving voltage quality, crucial for the smooth operation of high-speed and metro trains.

In addition, ABB is scaling up its portfolio of SiC-based battery chargers and auxiliary converters, representing a leap in energy efficiency, thermal management, and compactness. These products are especially relevant for both new train-sets and retrofitting projects, where space constraints and energy performance are key considerations.

To support this technological leap, ABB continues to invest in local R&D, engineering, and manufacturing capabilities at our facilities in Vadodara and Bengaluru. This not only strengthens our alignment with the government’s Atmanirbhar Bharat (self-reliant India) initiative but also ensures faster delivery, better serviceability, and solutions tailored to Indian Railways’ unique needs.