Why MODERN INFRASTRUCTURE fails to achieve its design life

Modern infrastructure is meant to provide safe, long-lasting solutions to growing urban populations, industrial expansion, and transportation demands. The design life of critical structures like bridges, roads, and buildings often ranges from 50 to 100 years. However, premature infrastructure failure has become a frequent global phenomenon, leading to significant economic losses, disruptions, and risks to human life. Globally and in countries like India, the gap between the intended lifespan and the actual durability of infrastructure is widening due to various technical, environmental, and operational factors.

This article critically analyzes the root causes of infrastructure deterioration, the consequences of these failures, and the technical solutions that can enhance structural durability, prolong service life, and minimize the need for costly repairs and rehabilitation.

Key causes of premature infrastructure failures

Poor material quality and construction practices: The quality of materials used in construction has a direct impact on the long-term performance of infrastructure. Substandard materials, such as low-grade concrete or ungraded aggregates, lead to early deterioration. Often, poor construction practices, like improper curing of concrete or inadequate compaction, further weaken the structure.

• Global example: The collapse of the Hyatt Regency Walkway (USA, 1981) was due to improper connections in the design and material defects during construction, resulting in the tragic loss of 114 lives. • Indian example: The Majerhat Bridge in Kolkata collapsed in 2018, and investigations pointed to the poor quality of materials used during repairs and the lack of regular inspections as major causes. Similar failures in India reveal that up to 20-30% of infrastructure projects are prone to early distress due to poor material selection and quality.

• Global example: The collapse of the Hyatt Regency Walkway (USA, 1981) was due to improper connections in the design and material defects during construction, resulting in the tragic loss of 114 lives. • Indian example: The Majerhat Bridge in Kolkata collapsed in 2018, and investigations pointed to the poor quality of materials used during repairs and the lack of regular inspections as major causes. Similar failures in India reveal that up to 20-30% of infrastructure projects are prone to early distress due to poor material selection and quality.

Corrosion of reinforced steel: Corrosion is one of the most prevalent causes of structural distress, especially in regions with high humidity, coastal exposure, or pollution. The corrosion of steel reinforcement inside concrete structures is accelerated by inadequate concrete cover, the presence of chlorides (from saltwater or de-icing salts), and carbonation, which reduces concrete’s alkalinity.

• Global example: The Morandi Bridge in Italy, which collapsed in 2018, was severely affected by corrosion of its steel cables. Over the years, environmental exposure to salty coastal air corroded critical structural components, leading to catastrophic failure. The cost of rebuilding was over €500 million.

• Indian example: Coastal infrastructure such as the Bandra-Worli Sea Link in Mumbai is subjected to aggressive environmental conditions. Corrosion-related maintenance costs for structures in Indian coastal regions are estimated to be ₹1,200 crores annually, adding a significant burden to public infrastructure budgets.

Overloading beyond design capacity: Many modern infrastructures are built with specific load-bearing capacities in mind, which are often exceeded over time due to population growth, increased vehicle load, and industrial expansion. This overloading leads to premature fatigue, stress fractures, and eventual failure of bridges, roads, and buildings.

• Global example: The I-35W Mississippi River Bridge in the USA collapsed in 2007 due to the increased traffic loads and inadequate maintenance of steel girders. This incident emphasized the critical need to monitor infrastructure loads in high-traffic regions. • Indian example: The Mumbai-Pune Expressway, one of the busiest highways in India, was not designed for the level of heavy truck traffic it currently carries. The National Highways Authority of India (NHAI) reports that overloading of trucks is responsible for 40% of highway pavement distress in India, leading to cracks, rutting, and frequent repairs.

• Global example: The I-35W Mississippi River Bridge in the USA collapsed in 2007 due to the increased traffic loads and inadequate maintenance of steel girders. This incident emphasized the critical need to monitor infrastructure loads in high-traffic regions. • Indian example: The Mumbai-Pune Expressway, one of the busiest highways in India, was not designed for the level of heavy truck traffic it currently carries. The National Highways Authority of India (NHAI) reports that overloading of trucks is responsible for 40% of highway pavement distress in India, leading to cracks, rutting, and frequent repairs.

• Indian example: The Mumbai-Pune Expressway, one of the busiest highways in India, was not designed for the level of heavy truck traffic it currently carries. The National Highways Authority of India (NHAI) reports that overloading of trucks is responsible for 40% of highway pavement distress in India, leading to cracks, rutting, and frequent repairs.

Inadequate maintenance and inspection regimes: Regular maintenance and periodic inspections are crucial to identifying and addressing potential structural weaknesses before they result in failures. In many countries, especially developing ones, the lack of a structured maintenance system or the diversion of funds allocated for maintenance leads to overlooked safety concerns and premature deterioration.

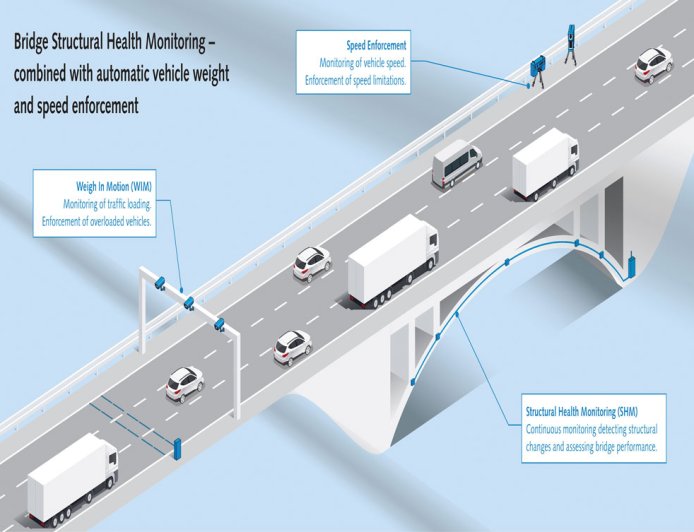

• Global example: Japan's well-structured asset management systems for infrastructure use advanced technologies like Structural Health Monitoring (SHM) to detect early signs of distress. In contrast, a lack of routine inspections contributed to the failure of the New Orleans levee system* during Hurricane Katrina in 2005.

• Indian example: Across India's urban flyovers and highways, particularly in metro cities, 40% of infrastructure is at risk due to deferred or neglected maintenance. Several audits by India's Comptroller and Auditor General (CAG) have revealed that inadequate inspections have been a key factor in the deterioration of bridges and roads, leading to emergency repairs costing billions of rupees annually.

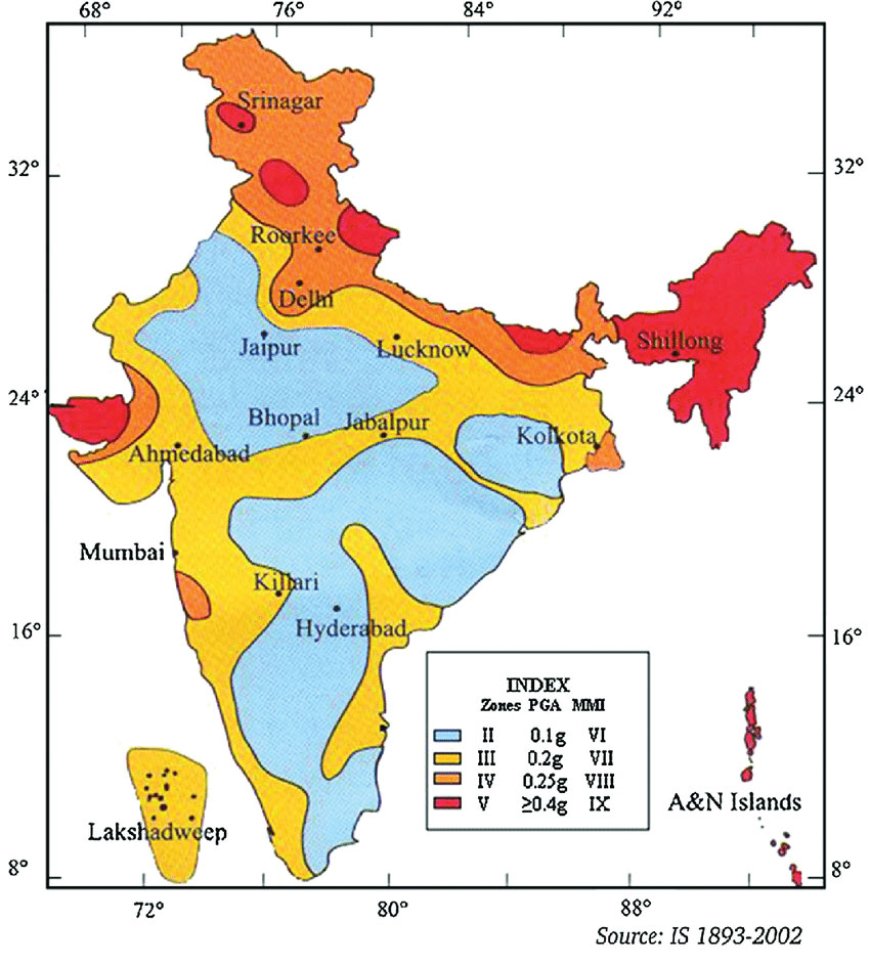

Seismic vulnerability: Seismic activity is another key factor contributing to the premature failure of infrastructure, especially in earthquake-prone areas. Buildings and bridges that are not designed to withstand seismic forces are at significant risk of collapse during earthquakes, causing loss of life and infrastructure damage.

• Global example: The Northridge Earthquake (USA, 1994) caused severe damage to several freeways and bridges, highlighting the need for seismic retrofitting of aging infrastructure.

• Indian example: In India, cities like Delhi and Gujarat, which are situated in seismic zones, still have a considerable amount of infrastructure that is not built to seismic codes. Recent earthquakes, such as the 2001 Gujarat Earthquake, showed the vulnerability of buildings and bridges in seismic-prone regions due to non-compliance with structural safety standards.

Climate change and environmental impact: The effects of climate change, such as increased flooding, rising sea levels, and extreme weather events, have accelerated infrastructure deterioration worldwide. Prolonged exposure to higher temperatures also weakens materials, while frequent cycles of wetting and drying increase concrete's susceptibility to cracking and scaling.

• Global example: The UK’s flooding in 2015 caused the failure of over 200 bridges and roads, with repair costs reaching £1.3 billion. These climate-induced failures underscored the importance of designing infrastructure to withstand future climate risks.

• Indian example: Climate-related deterioration is a major issue in India. For instance, the 2013 Uttarakhand floods severely damaged roads and bridges, with an estimated cost of repair and rebuilding exceeding ₹3,000 crores. Many Indian cities face infrastructure degradation due to unpredictable monsoon cycles, leading to waterlogging and damage to road surfaces.

Consequences of premature infrastructure failures

Financial costs: Premature failure of infrastructure results in enormous financial costs due to the need for unplanned repairs, rebuilding, and associated downtime. Globally, the cost of maintaining and rehabilitating failing infrastructure runs into trillions of dollars.

• Global data: In the United States, it is estimated that $2.6 trillion will be needed by 2029 to repair and replace aging infrastructure, as noted in the American Society of Civil Engineers (ASCE) 2023 Infrastructure Report Card.

• Indian data: India faces significant costs due to frequent repairs of highways, bridges, and urban infrastructure, amounting to Rs 3.5 lakh crore annually, according to the National Highways Authority of India (NHAI).

Loss of human lives and public safety risks: Structural failures pose significant risks to human life, particularly when they occur suddenly, without warning. The loss of life from bridge collapses, building failures, and dam bursts highlights the grave consequences of premature infrastructure deterioration.

Loss of human lives and public safety risks: Structural failures pose significant risks to human life, particularly when they occur suddenly, without warning. The loss of life from bridge collapses, building failures, and dam bursts highlights the grave consequences of premature infrastructure deterioration.

• Global example: The collapse of the Genoa Bridge in Italy in 2018 resulted in 43 fatalities, largely due to the lack of timely repairs despite visible signs of corrosion and distress.

• Indian example: In India, the Vivekananda Road Flyover collapse in 2016 in Kolkata claimed 27 lives, raising concerns about the quality of construction and the lack of adequate inspections during the flyover’s construction.

Operational and economic disruptions: Premature infrastructure failure leads to widespread disruptions in economic activities, transportation, and public services. This can result in traffic delays, lost productivity, and additional costs associated with emergency repairs.

• Global example: The closure of the San Francisco-Oakland Bay Bridge for seismic retrofitting and emergency repairs caused a major disruption in one of the busiest transit corridors in the US.

• Indian example: The Mumbai Metro faced delays and disruptions due to structural defects in the elevated sections, with repair costs reaching several hundred crores. These disruptions negatively impact commuters and the overall economy.

Solutions for prolonging structural durability

Advanced construction materials: The use of high-performance concrete (HPC), fiber-reinforced polymers and self-healing concrete can significantly extend the lifespan of infrastructure. These materials are designed to resist corrosion, withstand extreme temperatures, and maintain structural integrity under heavy loads.

• Global example: The Millau Viaduct in France, constructed with advanced materials designed to resist environmental degradation, is expected to last over 120 years with minimal maintenance.

• Indian example: High-performance concrete is being increasingly used in the construction of metro systems in cities like Delhi and Mumbai, helping to extend the durability of these structures in harsh urban environments.

Corrosion protection technologies: The use of cathodic protection, epoxy-coated rebar, and anti-corrosion coatings can slow down or prevent the corrosion of steel reinforcement. Regular monitoring and timely application of protective coatings can also help mitigate corrosion risks.

Corrosion protection technologies: The use of cathodic protection, epoxy-coated rebar, and anti-corrosion coatings can slow down or prevent the corrosion of steel reinforcement. Regular monitoring and timely application of protective coatings can also help mitigate corrosion risks.

• Global example: Cathodic protection systems are widely used in the Dubai Metro to protect its steel components from corrosion due to the city's highly corrosive soil and groundwater conditions.

• Indian example: The Mumbai Coastal Road Project incorporates corrosion-resistant materials and coatings to enhance durability against aggressive coastal conditions.

Improved design codes and standards: Updating design codes to account for future climate risks, seismic vulnerabilities, and modern traffic loads can enhance infrastructure resilience. Regularly revising these codes and ensuring compliance is critical for long-term durability.

• Global example: Japan’s stringent seismic building codes, enforced after the 1995 Kobe earthquake, have significantly reduced the risk of building collapse during subsequent earthquakes.

• Indian example: The Indian Roads Congress (IRC) and the Bureau of Indian Standards (BIS) have introduced new guidelines for designing roads and bridges to withstand heavy traffic and environmental stressors, but enforcement remains a challenge.

Digital monitoring and predictive maintenance: The integration of Structural Health Monitoring (SHM) systems, which use sensors to continuously monitor infrastructure conditions, can provide early warnings of distress. Predictive maintenance, driven by real-time data, allows authorities to schedule repairs before failures occur.

• Global example: The Golden Gate Bridge in San Francisco employs SHM technologies to monitor the effects of wind, traffic, and seismic activity, ensuring timely interventions.

• Indian example: SHM is being incorporated into major projects like the Mumbai Trans Harbour Link, with sensors embedded in key structural elements to detect corrosion, vibrations, and load stresses in real-time.

Conclusion

Premature infrastructure failures are a global challenge, exacerbated by poor construction practices, environmental degradation, material corrosion, and insufficient maintenance. The consequences are not only economic but also impact public safety and disrupt essential services. However, solutions do exist. By leveraging advanced materials, adopting new corrosion protection technologies, enforcing updated design codes, and employing digital monitoring systems, we can significantly prolong the lifespan of modern infrastructure.

Authorities must prioritize proactive and preventive measures to avoid the costly cycle of failure and repair, ensuring that future infrastructure is both durable and resilient.

|

Dr S B Hegd Ex-President – Manufacturing (Cement Industry); Professor, Jain College of Engineering and Technology, Hubli, India; and Visiting Professor, Pennsylvania State University, USA |