CDOT alleviates severe bottlenecks along mountain corridor

Bentley Technology provides a digital visual environment, saving 50,000 work hours and USD 7 million in project costs.

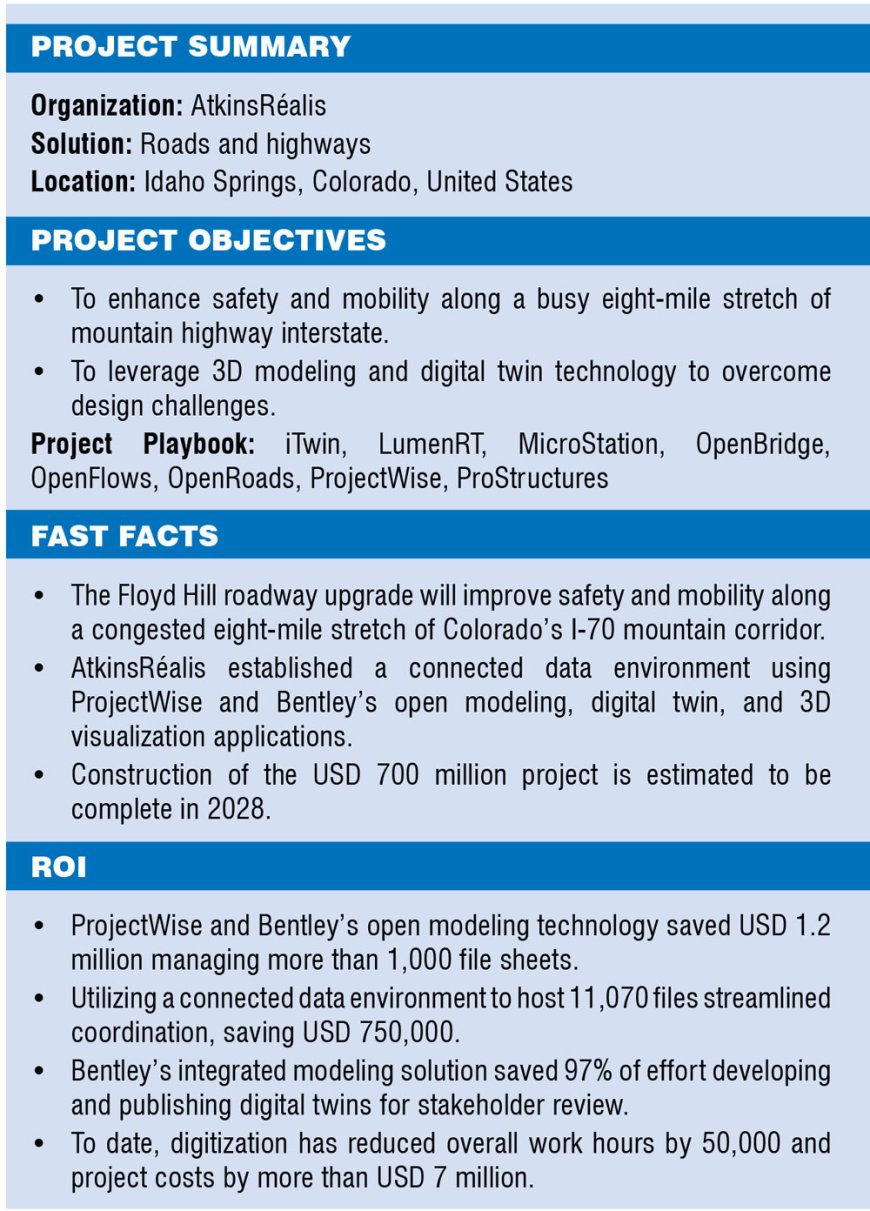

Colorado’s Interstate 70 (I-70) mountain corridor leads to some of the state’s most popular recreational destinations and serves as a main east-west throughway for long-haul trucks transporting goods to Summit County and the Western Slope. To enhance safety and mobility along the notoriously congested and treacherous highway, Colorado Department of Transportation (CDOT) is upgrading an eight-mile stretch passing through Floyd Hill, approximately 25 miles west of Denver. Upon completion, the USD 700 million project will address the severe bottleneck at Floyd Hill, improving traffic flow and design speeds, as well as access at major interchanges and frontage-road intersections. The project will also increase stopping sight distance along horizontal roadway curves, improving safety throughout the corridor.

AtkinsRéalis is the lead engineer and designer working with CDOT to determine optimal solutions for realigning the roadway, rebuilding pavement and bridges, and replacing aging infrastructure amid the spectacular mountain setting. The upgrade of the busy interstate segment includes adding a westbound tolled express lane and eastbound auxiliary lane, constructing a missing two-mile frontage-road section for better emergency response, as well as implementing environmental mitigation works. “These project improvements will reduce congestion, expand the highway for more capacity, replace six existing bridges, make improvements to interchanges and intersections in the area, and revamp the design of the highway,” said Samuel Worthy, National BIM Manager for roads and highways at AtkinsRéalis. The project will also enhance wildlife connectivity, air and water quality, stream conditions, and pedestrian trails and recreation.

Topography, environmental, and coordination challenges

The mountainous topography and creek running along the interstate segment presented significant design challenges with realigning the roadway, compounded by tight site constraints. Also, the environmental mitigation works included adding two new wildlife passageways underneath bridge spans to connect previously separated natural areas, as well as building the new travel lanes and upgrading interchange access. “There are many site-specific challenges and constraints, such as minimizing the impact to adjacent environmentally sensitive areas, reducing impacts to floodways, reducing rock excavation, and phasing the construction works to reduce impact to existing roadways,” said Worthy.

Managing this high-visibility project required utilizing a construction manager/general contractor (CMCG) method, where the contractor and construction manager work together to provide input throughout the project. Therefore, AtkinsRéalis needed to communicate and coordinate not only among the multiregional, multidiscipline design team, but also with a wide range of external stakeholders and the public. AtkinsRéalis had to interact and present various design alternatives to CDOT and the community, necessitating a streamlined collaborative technology approach. “The involvement of many external stakeholders requires direct access to the design files as they progress in real time,” said Worthy. To address these challenges and deliver the project as a CMGC project, AtkinsRéalis needed integrated digital technology.

Leveraging collaborative modeling and digital twin technology

With the help of Bentley’s collaborative 3D modeling and digital twin applications, AtkinsRéalis tackled the mountain project by creating realistic models available to the entire team and stakeholders in real-time as the design progressed. “To accomplish this level of real-time coordination, ProjectWise was utilized as the common data environment,” said Worthy. Combined with iTwin to build digital twins, OpenRoads and OpenBridge for collaborative geometric design and bridge modeling, and LumenRT for visualization, AtkinsRéalis streamlined data management. They then built a project digital twin that they shared in various formats, including static models and video animations. “The applications allowed us to create 3D models quickly and evaluate geometrics and specific parameters such as sight distance,” said Alan Carter, project manager and lead roadway designer at AtkinsRéalis. “We could attend meetings with stakeholders and fly around the model to get a sense of what the project will look like.”

The compatibility and connectivity among Bentley’s applications played a key role in the project’s success. Working in a connected modeling environment, fully configured and managed on ProjectWise, enabled the entire team and external consultants to utilize the same digital library files. The library was automatically upgraded and integrated as modifications were made, ensuring standardized design. Historically, exporting and refining models to create a project digital twin had been time-consuming and difficult. “On Floyd Hill, the project team developed a workflow to create reality meshes from OpenRoads ConceptStation, bring them into OpenRoads Designer in container files, export the federated project 3D model (with all discipline models) into LumenRT, and then create videos, LiveCube files, and 360-degree tours to be utilized on the public project website,” said Worthy. Bentley’s integrated, open 3D modeling and digital twin solution helped the team to communicate and visualize dozens of alternative designs and fully evaluate construction impacts and constructability, determining an optimal roadway design to meet the project goals.

Digitalization delivers savings and supports sustainability

Leveraging Bentley applications to establish a digital visual context helped AtkinsRéalis determine solutions to many site-specific challenges, such as adding a third westbound lane. Using 3D collaborative modeling, they developed a design that elevates a portion of the new westbound lane on bridge structures to fit all the components into a tight space and flatten out some previously sharp curves. Working in a digital environment also saved significant time and money. “Communication and coordination with external subconsultants are seamless with the Bentley-hosted ProjectWise data source, saving 5,500 hours in coordination [time],” said Worthy. AtkinsRéalis saved USD 1.2 million managing more than 1,000 file sheets by using Bentley applications. Utilizing a connected data environment to host 11,070 files streamlined coordination, saving USD 750,000. In addition, working in a digital environment saved 97% of effort when developing and publishing digital twins for review. To date, digitization has reduced overall work hours by 50,000 and project costs by more than USD 7 million.

With regard to sustainability, establishing a digital visual context helped mitigate impacts to the surrounding environment while enhancing wildlife connectivity, air and water quality, stream conditions, and recreation. Bentley’s 3D modeling and visualization software facilitated effective communication of the design intent to environmental and social experts, providing a more holistic understanding of the final built environment and ensuring sustainable design solutions. Using the digital twin models to visualize the impacts of the design to views along the Greenway Trail and Clear Creek ensured that project improvements did not detract from the surrounding natural beauty along the corridor. They also provided solutions to create approximately 1,500 feet of new pedestrian trails for areas previously inaccessible in Clear Creek Canyon.

Looking ahead, AtkinsRéalis sees many opportunities to apply digital twin technology beyond design and construction, leveraging data sensors and IoT devices to manage assets and monitor roadway performance. “We’ve learned how to use the full power of these tools, but we’re just getting started,” said Carter.

Meg Davis, Enterprise marketing director for Bentley Infrastructure Cloud

Email: meg.davis@bentley.com