Challenges in construction of oil & gas pipelines in India

India is the third-largest energy consuming nation in the world, after the US and China. Energy consumption is increasing at an accelerated pace, mainly on account of faster urbanization, adverse climatic condition requiring cooling/heating, industrialization, population growth etc. India is the highest populated country on earth with over 1.4 billon people.

India is an import-dependent country for energy, as we import nearly 85% of our crude oil requirement, nearly 50% natural gas in the form of LNG, and nearly 50% of LPG. The vast coastline facilitates such import and pipelines connect coast to refineries and other consumption areas, which passes through hinterland. From refineries, petroleum products and LPG pipelines are originated for distribution and effective supply chain management. Similarly, from producing fields, oil & gas is transported through pipelines to refining, treatment plants, fractionalization units and distribution. This promotes the pipeline infrastructure in the country and increasing energy demand is key driver for growth.

India presently has nearly 70,000 km of cross-country oil & gas pipelines. Another 25,000 km of oil & gas trunk pipelines are under construction. Pipeline is the preferred mode of transportation of energy, on account of its environment-friendliness, economics, reliability, energy efficiency and sustainable mode. Some of these include the gas pipelines under Pradhan Mantri Urja Ganga Yojna, longest LPG pipeline in the world etc. In the pipeline, the energy is imparted to flowing fluid whereas, container (pipe) remains stationary, in other modes of transportation like railway, ship and road, one side the empty container is transported back thus requiring additional energy.

The challenges are faced by pipeline operators right from pre-project activities like obtaining permissions for pipeline crossings. The right of way acquisition (ROW), land acquisition for stations, sectionalizing valve locations, repeater stations etc. Normally, the following permissions are necessarily required like Road Crossings - National Highway, State Highways, City and Village roads; Railway line crossing; and River and water course crossing. Each such permission required repeated follow ups, pursuation and it’s time consuming.

Laying pipeline through forest areas, i.e. reserve forest, protected forest and unclassified forest is another challenge. Similarly, passing through the defence lands, CRZ areas and government lands, a separate set of permissions are required. The environment clearance is obtained through structured procedure including public hearing. The explosive clearance is taken under petroleum act 1934. The pipeline involving off-shore/sea-creek maritime board permission is obtained. Usually getting this permission for cross-country pipelines takes almost a year or more. Generally, 28-36 months period is allocated for pipeline project, which post construction design validation, testing and set of permissions for commissioning.

The right of way acquisition is done through Petroleum and Mineral Pipeline Act 1962 (PMP Act), the cultivated land is acquired for laying the pipeline and compensation is paid to farmers for land and standing crops. The cost of acquisition has gone considerably high and often pipeline operators face challenges in settling the compensation matter. The acquisition process involved state and Central Government. After survey section 3(1) notification is issued for intension of acquiring the land for pipeline laying, objections are invited and hearing is done by competent authority. After hearing the notices and resolving the matter, the land is acquired under 6(1) through gazette notifications of PMP Act. And possession of land is taken for opening of Right of Way (ROW). As per section 10 (1) the land owner shall be compensated for any loss and amount to be decided by competent authority appointed under the act. However, many disputes arise on account of the same.

Challenges

During the construction, the pipe is left in the ROW awaiting clearance for construction, is likely to get damage through vehicular movements or agriculture equipment movements in vicinity of the pipe. In horizontal directional drilling (HDD), during the pipeline pulling through bore hole, the pipe coating might get damage due to any leftover pebbles/stone in bore hole. This damaged coating is prone to corrosion thus poses risk to pipeline life.

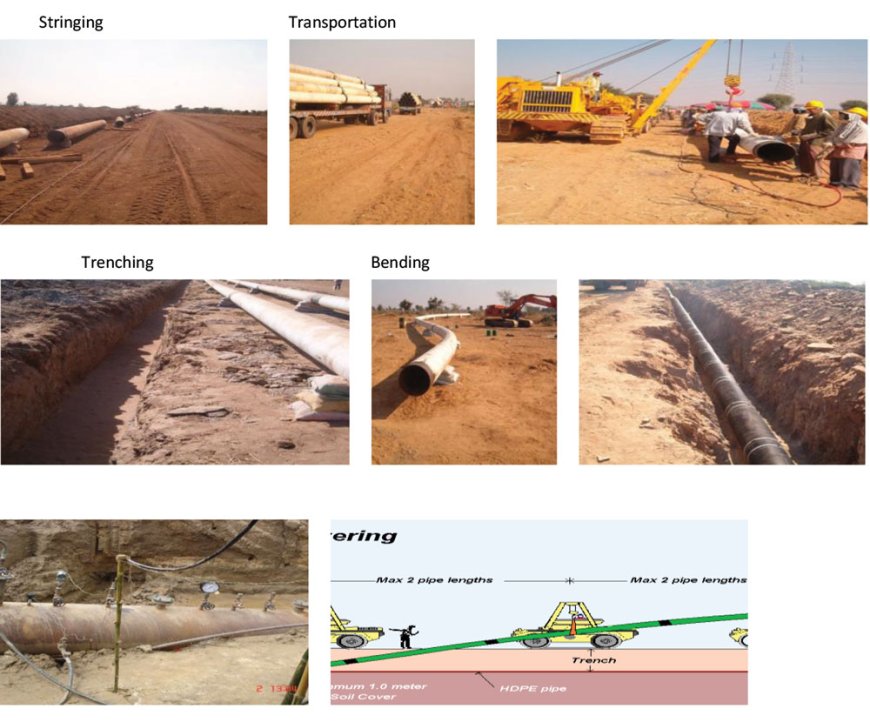

After obtaining the above-mentioned permissions, acquisition of land and right of way, procurement of materials like pipe, undertaking factory coating of the pipelines, procurement of station equipment, valves, prime movers, firefighting, electrical supply, instrumentation control system, is done as parallel action. Upon receipt and delivery of the sizeable quantity of pipes at stock pile, ROW opening and construction work is undertaken through reputed construction companies.

Often farmers form pressure groups and express their dissatisfaction on account of compensation by sit on dharna, thus delaying construction. Although, over the period of time, the compensation has been substantially enhanced to several times than previously adopted. The farmers agitation affects the project schedule and associated benefits. The prolonged keeping the coated pipeline at right of way is likely to get damaged due to vehicular/agriculture equipment etc.

The pipeline is laid both through open cut, i.e. excavating the trench, welding and lowering of the pipeline inside the trench and also through HDD across the major rivers, water courses, sea creek, busy national and state highways etc. In case of HDD, the surface like road, river is least affected, however, cost of HDD is much higher 7-10 times of normal construction.

Summary

There are many challenges in pipelines project execution. Local communities and infrastructure often experience disruption and inconvenience during construction. The oil & gas industry pipeline construction is one of the most complex projects any organization can undertake. External bottlenecks can cause delays, excessive costs, and a variety of other problems. Some of the common problems are listed below:

Infrastructure of shortfall: The majority of new pipelines are being built in areas with existing oil and gas infrastructure, thus requiring criscrossing or parallel laying causing issues of permissions and cathodic protection interference etc, with adjoining infrastructure.

Utility interference: Underground pipelines often share subsurface space with existing utilities such as gas lines, water pipes, and electrical cables. The risk of interference and potential damage to these utilities pose a significant challenge.

Right of way issues: A significant concern with pipeline construction is the amount of land required. It can be challenging to secure the right of way for building the pipeline because of this, in most cases, eminent domain, which covers interstate oil and gas pipelines.

Regulatory compliance: Underground pipeline construction is subject to various local, state, and central regulations. Obtaining permits and ensuring compliance with safety and environmental standards can be a time-consuming and complex process. Delays in regulatory approval can hinder project timelines and increase costs.

Difficult terrain: A pipeline construction project must typically account for terrain challenges due to the long distances covered by pipelines. Multiple factors could contribute to this, such as extreme weather conditions, mountainous terrain, and elevation changes.

Geopolitical issues: Pipeline construction of the projects typically cross several political jurisdictions, including municipalities, counties, and states. Often problems are required to resolved at each level.

Conclusion

India has made substantial progress in the pipeline construction and in a couple of months, one large HDD section of over 4 km across the Brahmaputra River was successfully done in North-East part of the country. Similarly, the fast track construction using automatic and semi-automatic welding and improved inspection methodology of Ultrasonic Testing has remarkably improved the inspection of weld quality thus avoiding the costly and time-consuming repetition. The inspection and preserving the pipe during construction are big challenges, which present operators, and construction agencies geared up for meeting. The software-based GIS enabled project monitoring and drone-based surveillance have become handy tool for project managers for linear projects like pipelines. Apart from project execution, the oil & gas pipelines face challenges throughout its operating life like corrosion, third-party damage, interference from other structures, urbanization, encroachments etc.

Underground pipeline construction is a complex and challenging process, but it is essential for delivering critical infrastructure services. By understanding and addressing the challenges of underground pipeline construction, project teams can provide safe, reliable, and environmentally friendly pipelines.

|

Dr Anand Kumar Tewari AMPP India (Formerly NACE India) |