Concrete mix design: Innovations, challenges and research directions

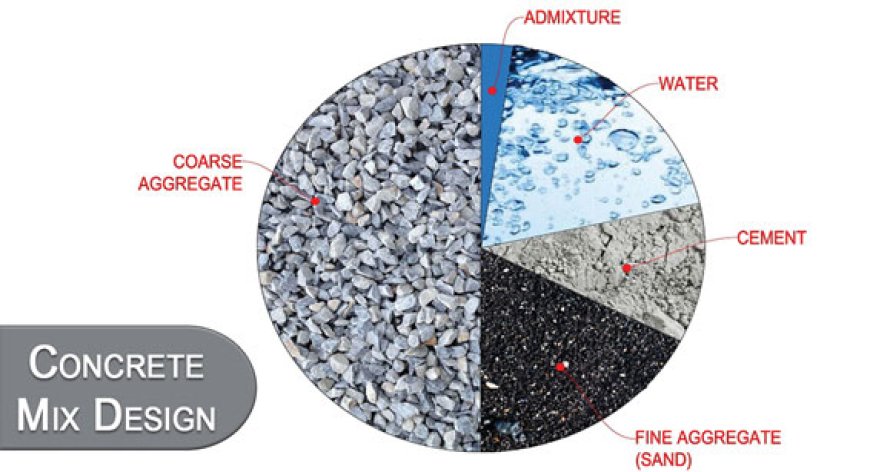

Concrete is the most widely used construction material globally, with applications ranging from simple sidewalks to massive infrastructure projects like dams and skyscrapers. The essence of concrete mix design lies in selecting appropriate ingredients—cement, aggregates, water, and admixtures—and determining their optimal proportions to achieve desired properties such as workability, strength, and durability.

Traditionally, mix design has focused on empirical methods and standard practices, such as those outlined in IS 10262, ACI 211.1, and other guidelines. However, the increasing complexity of construction projects, coupled with the need for sustainable practices, has driven the evolution of concrete mix design into a more scientific and innovative domain.

Recent advancements include the use of supplementary cementitious materials (SCMs) like fly ash, silica fume, and ground granulated blast furnace slag (GGBFS), which improve performance and reduce the carbon footprint. High-performance concrete (HPC) and ultra-high-performance concrete (UHPC) have emerged, offering superior strength and durability for demanding applications. Additionally, the integration of nanotechnology and self-healing mechanisms represents a significant leap forward in enhancing concrete properties.

Research directions and future trends

The field of concrete mix design is rich with ongoing research and innovative trends that promise to revolutionize how concrete is produced and used. Below, we explore several key areas of research and future trends in detail.

Advanced computational modeling and simulation

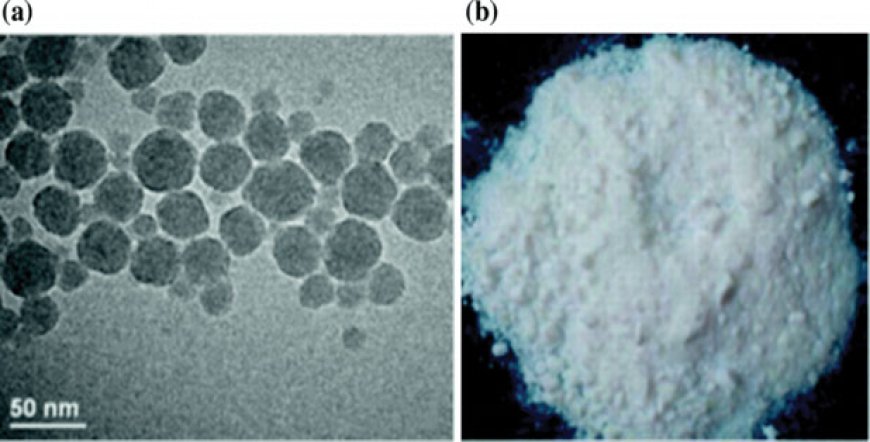

Multi-scale modeling: Multi-scale modeling integrates data from different scales—nano, micro, and macro—to predict the behavior of concrete more accurately. For instance, the use of multi-scale models can help understand the impact of nano-silica on the microstructure of cement paste, which in turn affects macro-level properties like strength and durability. Researchers are developing sophisticated software tools that can simulate the entire lifecycle of concrete structures, predicting how they will perform under various environmental conditions over time.

ML and AI: Machine learning (ML) and artificial intelligence (AI) are transforming concrete mix design by enabling the analysis of vast datasets to identify optimal mix proportions. Algorithms can predict the properties of concrete based on different mix combinations, reducing the need for extensive experimental testing. For example, AI-driven models can optimize the mix design for specific performance criteria such as high early strength or enhanced durability, significantly shortening the design process and improving accuracy.

Sustainable concrete technologies

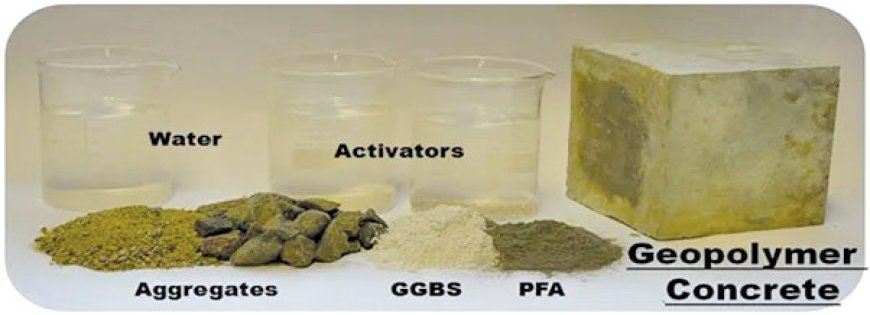

Geopolymer concrete: Geopolymers are inorganic polymers formed by the reaction of aluminosilicate materials with alkaline solutions. Geopolymer concrete (GPC) offers a sustainable alternative to traditional Portland cement concrete (PCC) by utilizing industrial by-products like fly ash and slag, which significantly reduces CO2 emissions. Studies have shown that GPC can reduce carbon emissions by up to 80% compared to conventional concrete. Ongoing research focuses on optimizing mix designs for various applications and improving the durability and mechanical properties of GPC.

Recycled aggregates: The use of recycled concrete aggregates (RCA) is an essential aspect of sustainable construction. RCA helps reduce the consumption of natural aggregates and minimizes waste from demolition activities. Research indicates that RCA can replace up to 30% of natural aggregates without significantly compromising the mechanical properties of concrete. Innovations in processing and quality control are improving the consistency and performance of RCA, making it a viable option for more applications.

High-performance and ultra-high-performance concrete

Reactive powder concrete (RPC): RPC is a type of ultra-high-performance concrete (UHPC) that achieves compressive strengths exceeding 200 MPa. RPC utilizes fine powders, a low water-cement ratio, and steel fibers to enhance its mechanical properties. Research is ongoing to improve the cost-effectiveness of RPC and expand its applications in infrastructure projects requiring exceptional durability and load-bearing capacity.

Self-compacting concrete (SCC): SCC is designed to flow and compact under its own weight without the need for mechanical vibration. This property makes SCC ideal for complex forms and densely reinforced structures. Innovations in admixtures and mix design are enhancing the flowability and stability of SCC, ensuring that it maintains its workability without segregation or bleeding. SCC is being increasingly adopted in high-rise buildings, bridges, and precast concrete elements.

Nanotechnology in concrete

Nano-silica: Nano-silica is a highly reactive form of silicon dioxide that can significantly improve the properties of concrete. By refining the pore structure and increasing the density of the cement paste, nano-silica enhances both the strength and durability of concrete. Research has shown that incorporating nano-silica can increase compressive strength by up to 20% and reduce permeability, making the concrete more resistant to chemical attacks.

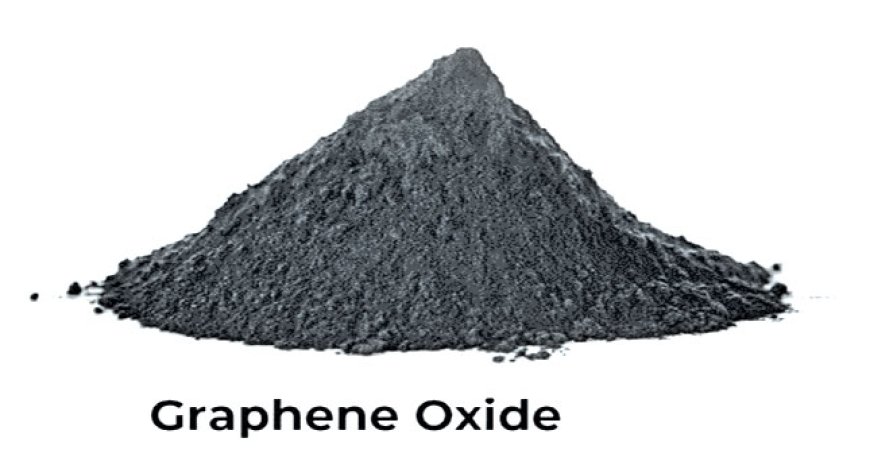

Graphene oxide: Graphene oxide (GO) is a derivative of graphene that can improve the mechanical and electrical properties of concrete. Studies have demonstrated that GO can increase the tensile strength and flexural strength of concrete by up to 50%. Additionally, GO-modified concrete exhibits improved crack resistance and durability, offering significant potential for use in high-performance and smart concrete applications.

Practical Implications and Case Studies

Millau Viaduct, France: The Millau Viaduct, one of the tallest bridges in the world, utilized high-performance concrete (HPC) to achieve exceptional strength and durability. The mix design incorporated silica fume and high-range water reducers to meet the stringent performance requirements. The use of HPC allowed for slender and aesthetically pleasing structural elements while ensuring long-term durability.

Burj Khalifa, UAE: The world’s tallest building, the Burj Khalifa, employed a specially designed high-strength concrete mix to withstand extreme loads and environmental conditions. The mix included fly ash, GGBFS, and advanced admixtures to achieve the required properties. The concrete used in the foundation and core of the Burj Khalifa had to meet stringent performance criteria, including high compressive strength and durability in a harsh desert environment.

Sustainable Construction Initiatives

Eco-friendly concrete in Australia: Researchers in Australia are developing eco-friendly concrete mixes using geopolymer technology. These mixes utilize fly ash and slag as alternative binders, significantly reducing CO2 emissions. Pilot projects have demonstrated the potential for these materials to replace conventional cement in various applications, including pavements, precast elements, and structural concrete.

Recycled aggregate concrete in the Netherlands: The Netherlands has been at the forefront of using recycled aggregates in concrete production. Projects like the reconstruction of highways and urban infrastructure have successfully incorporated high percentages of recycled aggregates, demonstrating the feasibility and benefits of sustainable concrete. The use of RCA in these projects has led to significant reductions in environmental impact and resource consumption.

Conclusion

Concrete mix design is a dynamic and evolving field that balances theoretical principles with practical considerations to achieve optimal performance. The integration of new materials and advanced technologies continues to enhance the capabilities of concrete, making it more durable, sustainable, and versatile. Ongoing research and development are essential to address the challenges of sustainability and durability, ensuring that concrete remains a cornerstone of modern construction.

Dr S B Hegde