We have established multiple advanced plants equipped with the latest technologies.

Nitin Jirafe,

How do you view the growth scenario of the Indian construction equipment industry?

As India's economy gains momentum, it is providing a significant boost to various sectors, including construction equipment (CE). In FY24, the CE industry experienced a remarkable 26% growth, driven by the government's focus on development and a robust pipeline of infrastructure projects. This growth trajectory is anticipated to continue in FY25 and beyond, fueled by investments and various initiatives by the government in this sector. According to the Indian Construction Equipment Manufacturers Association (ICEMA), the CE industry's impressive performance in FY23 was largely propelled by government initiatives, positioning India to potentially become the world's second-largest market for construction equipment by 2030. This growth is underpinned by substantial investments in infrastructure development, reinforcing India's potential as a global manufacturing hub.

As India is set to become the third-largest construction market globally, what opportunities do you visualize for the construction equipment industry?

Cummins has always been driven by the vision of powering the success of its customers. Focus on productivity, adoption of digital solutions, and addressing climate change are the key three trends that will shape the future requirements of the CE industry.

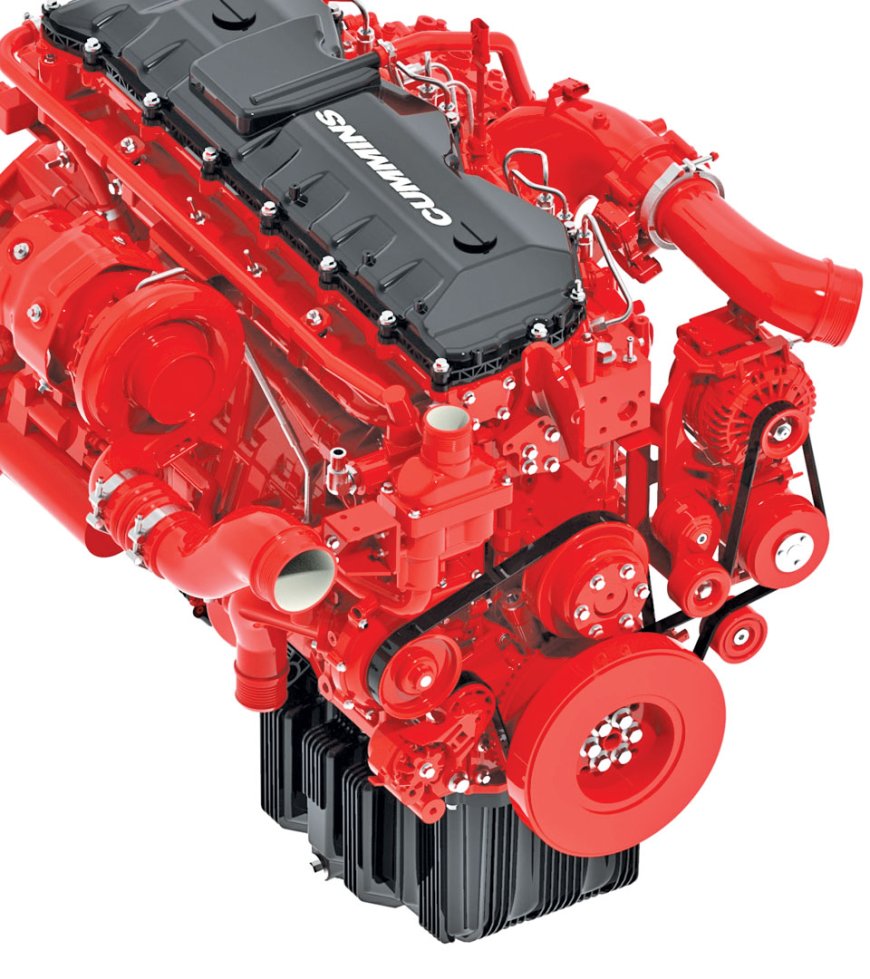

Cummins offers an array of products, in the 3.9 liter to 15 liter displacement, across a wide range of power from 80 hp to 450 hp, thus addressing the requirements of a wide variety of construction applications. Further to address specific regulatory needs, these engines are designed dedicatedly to meet non-regulated to the latest emission standards of CEV BSIV and upcoming CEV BSV. To meet the latest emission standards, we have closely integrated our engines with advanced after treatment systems. Cummins’ in-house expertise and manufacturing of after treatment systems enable us to deliver the best-in-class performance for the overall system.

As a technology leader, we constantly upgrade our products to introduce the latest technologies to the market and enhance performance in line with the changing market trends and needs of our customers. At the EXCON 2023, Cummins showcased its cutting-edge L10 and M15 platforms, highlighting the company’s commitment to innovation and industry-specific solutions.

As India is focusing on building infrastructure at a rapid pace, these engines are designed to deliver high power density to improve productivity with an overall better value proposition. These engines are aimed to enhance fuel efficiency and lower emissions, aligning with India’s goal of a cleaner environment.

How are you prepared to introduce more efficient and productive engines to meet customer demand in the future?

The government’s focus on the rapid development of infrastructure is driving the need for timely execution of projects. To enable this, efficient construction equipment with adequate power and reliability is required to maximize productivity. Cummins’ higher power density engines, along with the introduction of the latest L10 (10 liters) and M15 (15 liters) platforms will help provide OEMs the opportunity to launch bigger and more productive equipment. Further, the introduction of electronic engines enables OEMs to introduce telematics-enabled digital solutions that ensure adequate tracking, uptime, and reliability of the products, thereby delivering higher productivity.

As India is fast becoming a global manufacturing hub, how are you raising the benchmark of quality to cater the global market?

At Cummins, we are powered by our core value of Excellence, which is about staying focused and determined to produce the highest-quality products and services and consistently delivering superior results.

Investing in state-of-the-art manufacturing facilities in India, we have established multiple advanced plants equipped with the latest technologies. These facilities adhere to rigorous quality control measures and lean manufacturing principles, ensuring continual upgrades over time. By adopting global quality standards, our operations in India align with certifications like ISO 9001 and IATF 16949, guaranteeing consistent product and process quality. Leveraging Six Sigma, data analytics, artificial intelligence, and Industry 4.0 technologies, we enhance quality monitoring and predictive maintenance, proactively addressing quality issues. We prioritize supplier quality by collaborating closely with our supplier network in India, offering training and support to meet Cummins' stringent standards. Additionally, we invest significantly in upskilling our workforce through technical and quality-focused training programs, fostering a culture of quality consciousness. Our customer-centric approach involves closely collaborating with customers to understand their evolving quality needs, and adapting our products and services accordingly.

What is your current status of Make in India? What are your plans to scale up the Make in India initiative?

Cummins has been one of the leading global power solutions manufacturers for more than 103 years globally. In India, our rich history spans more than six decades, marked by the successful integration of our global and local technological expertise across a diverse range of off-highway applications. We remain committed and focused on delivering tailored, innovative solutions to cater to the domestic as well as internal markets to cater to diverse customer needs. Cummins India has won the national award for Export Excellence for exports made during the Financial Year 2019-2020 and 2020-2021 at their 52nd and 53rd National Exports Award function conducted earlier this year.

Powered by our commitment to building a sustainable future, we have recently inaugurated the Tata Cummins Pvt Ltd (TCPL) Green Energy Solutions plant, along with our JV partners Tata Motors. The plant will produce hydrogen-based internal combustion engines for medium and heavy commercial vehicles and other low to zero-emission technology products in India.

How is emission playing a major role in the current market scenario? What are the steps taken by you to bring in sustainability in your product range?

Amid rising concerns about climate change and greenhouse gas emissions, the construction equipment industry is gradually shifting towards alternative power solutions. Utilizing renewable energy in construction equipment helps lower carbon emissions and promotes more eco-friendly building practices. By leveraging renewable energy sources, construction companies can decrease their dependence on fossil fuels and make significant strides towards a more sustainable future.

Sustainability is a central focus for Cummins, both in India and globally. Accelera, a Cummins brand, is an energy technology company that offers low to zero-emission solutions to provide clean energy worldwide. We are making significant advancements globally and in India with hydrogen internal combustion engines (H2ICE), built on the fuel-agnostic platform. We are committed to our sustainability goals and aim to achieve carbon neutrality by 2050. Cummins strives to be a driving force for positive change in the B2B sector, delivering solutions that meet strict emissions standards and push the industry towards greater sustainability.

What will be trending in future in the construction equipment market? What is your vision to be a preferred solution provider to the construction and infrastructure sector?

As we explore the intricacies of the construction equipment industry in 2024, it's essential to acknowledge the dynamic trends and advancements shaping this critical sector. With technological innovation at its heart, the industry is not only expanding but also evolving, adapting to meet the ever-changing demands of construction projects worldwide.

Our vision as a preferred solution provider to the construction sector is to introduce advanced engines that meet the needs of our current customers and attract potential ones. We are dedicated to continuous innovation, developing new technologies such as hydrogen delivery systems and batteries, to ensure we remain at the forefront of the industry and consistently offer cutting-edge solutions.