Effectively reuse and recycle water in construction

With depleting natural resources, recycling and reusing water in the construction industry is crucial for sustainable development and conservation of resources. Water is a precious resource, and its efficient use and management are essential to minimize environmental impact and reduce overall costs.

Challenges today

Most large construction site being remote and located away from municipal limits of city have the below key challenges.

· Dependency on tankers for water supply at construction site

· Need for temporary construction of soak pits for managing sewage from portable toilets

· Cost of non-potable water starting from Rs 50 per KL sometimes up to Rs 120 per KL

· Disposal and disposal costs for sewage water/wastewater if any generated

· Onsite temporary/skid-based units for treatment of water/wastewater/sewage

· Implementing rainwater harvesting onsite with filtration/purification

How the process works

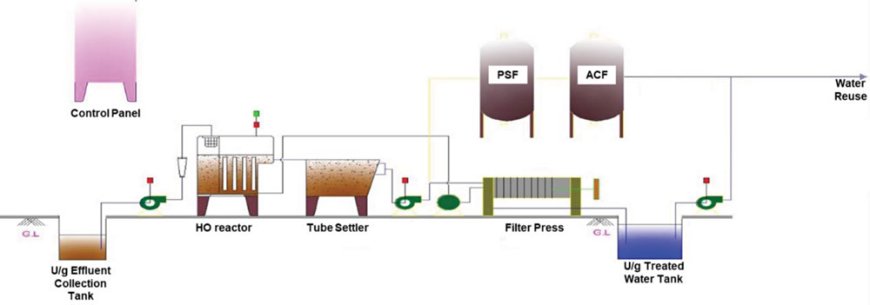

STEP 1: Raw effluent enters our EHO process reactor (with or without pH adjustment)

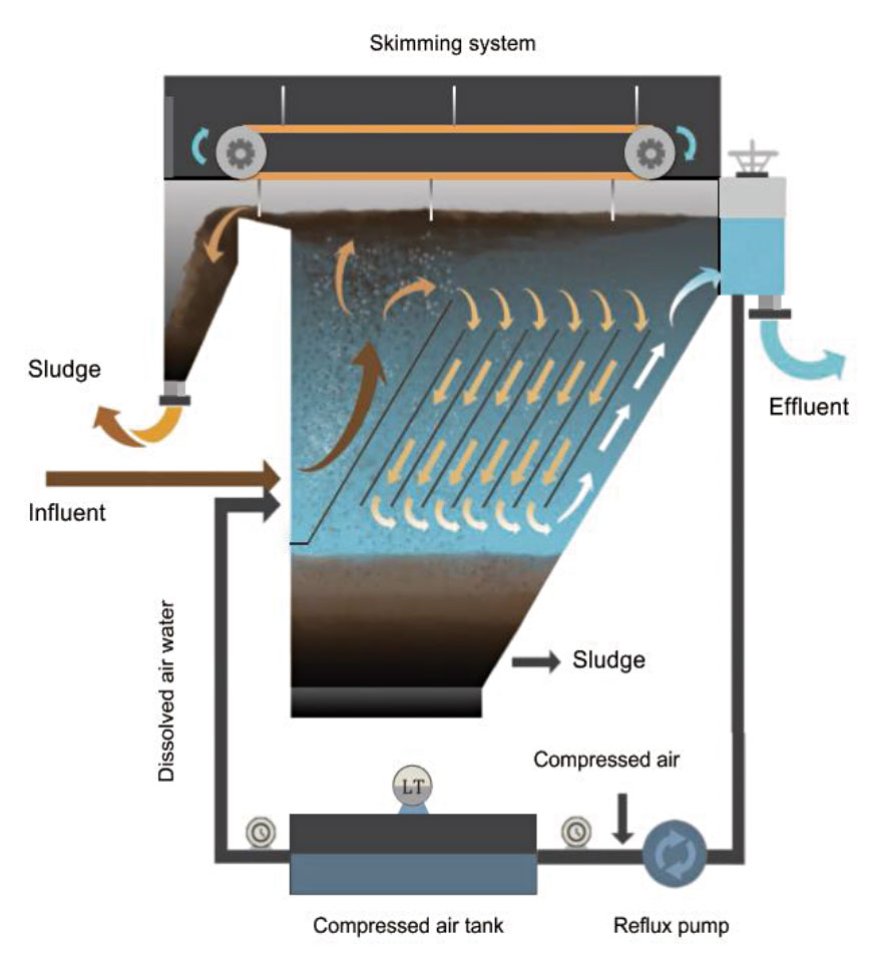

STEP 2: Reactions that take place in the EHO reactor, the pollutants (organic and inorganic) in the sewage effluent process fluid starts to disintegrate out of the fluid molecule and coagulate into heavier particles which collect (depending on the density of the pollutants) either at the bottom of the reactor tank or at top of the fluid as floating sludge solids which are skimmed off or filtered out.

STEP 3: The treated effluent is further fed to filtration equipment (a filter press or a screw press) for effective removal of the suspended solids.

STEP 4: The filtrate is further fed to a tertiary treatment through PSF + ACF for removal of any suspended solids, residual organics and any residual colour or odour for recycle and re-use for non-contact purposes.

The solution

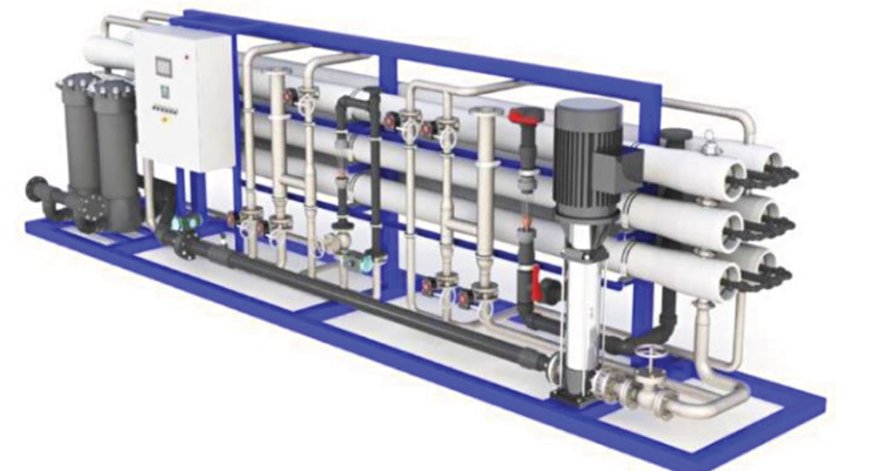

A fully skid mounted WWTP (can treat water/sewage/wastewater) plant that can treat the wastewater for recycle and re-use up to 95% water for non-contact uses - for concrete pre-mix preparation, concrete curing, for utilities & washing, toilet flushing, ground water soil settlement, gardening and many other possible uses.

We also offer such WWTP plants/skids on monthly rentals with a minimum contract commitment duration. Also, we can design-build-supply and offer truck or trailer or containerized modules on request.

Benefits

Reusing and recycling water in construction can bring many advantages for your project. It can help you save money on water bills, wastewater treatment, and disposal fees. Additionally, it can reduce your dependency on external water sources, while increasing your project's resilience to water scarcity and climate change. Furthermore, reusing and recycling water can improve the quality of water by removing pollutants and contaminants through natural or artificial processes. Finally, it can also enhance the reputation of your project as a green and sustainable one, potentially attracting more customers and investors who value environmental responsibility.

· 90% lesser space requirement v/s conventional systems - 6 m X 2 m for 30 KLD

· No noise, no bacteria, no toxicity, no foul smell – Suitable for public/residence

· Simple Switch ON Switch OFF operation

· Least maintenance

· Water treated water quality = Water feed water quality

· Fully automated plants using PLC possible

· Lesser sludge handling (60% lesser sludge compared to MBBR)

· Non-leach forming and non-hazardous sludge - can be used in landfill and construction as well

· Lesser overall real estate costs and almost no civil infra costs

How do I start?

To maximize the benefits of water reuse and recycling in construction, you should conduct a water audit to identify the sources, uses, and flows of water in your project, as well as set realistic and measurable targets and indicators for water reuse and recycling. Additionally, you should implement water-efficient technologies and techniques such as low-flow fixtures, rainwater harvesting, greywater recycling, stormwater management, and membrane filtration. Furthermore, it is important to adopt water-smart design and planning to reduce water demand and enhance water capture and reuse. Finally, engaging and collaborating with consultants, staff, contractors, suppliers, customers, and regulators can promote a culture of water stewardship and innovation in your project. In conclusion, by applying these strategies, you can improve the efficiency, quality, and sustainability of your project while creating a positive impact on the environment and society.

Amresh Mehta