We are aiming for those areas where we can offer solutions to improve the construction quality.

<meta name="description" content="construction infra ,fractional real estate,strata geosystems">

Gautam Dalmia

CDO, Strata Geosystems (India) Pvt. Ltd.

How do you view the progress of Indian construction industry?

The general construction market in India is doing well. However, from a conceptual approach, there is a need for faster infrastructure build as we are lagging in our network. Our cost of logistics is much higher than most of the other countries. So, better rail and road networks, container yards, port facilities, and supporting infrastructure are needed.

India is growing at a greater scale with a lot of financing available, but there is a need for people to focus on quality and to make the construction process more efficient and sustainable. Today, there are sectors which are still following classical ways of construction where there is a scope for adopting modern-and-state-of-the-art technologies, such as extensive but judicial use of geosynthetics, enabling faster construction at lower cost and, hassle-free construction. Roads & highways sector has seen the benefits and has adopted many of these solutions. Now, sectors like railways, water and others should adopt the new emergent technologies.

For us, the market is vast as it is and growing and the government has an aggressive vision on the construction market. It is just a matter of how to make it more efficient and provide the right quality.

What are your major products and solutions for the railways sector?

In railways, there are a few areas of concern. Earlier, the requirement for track speed was lower, but now Railways has a target to achieve a 160 km/hr track speed. We are coming from a slower track speed of 40-60 km/hr average (maximum 120 km/hr) and now we aim maximum of 160 km/hr. To achieve this, the track infrastructure must be upgraded. Generally, tracks go through deformation of the formation and the sub soil below.

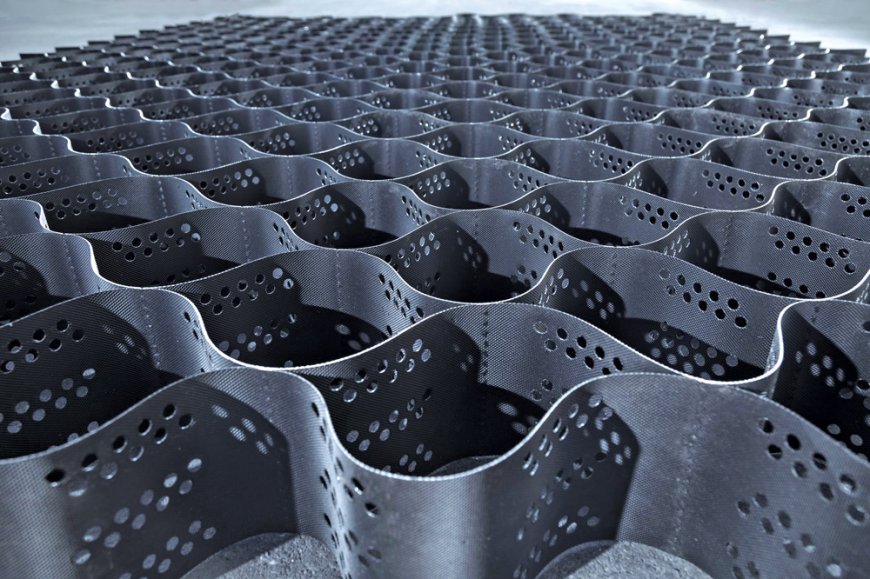

We at Strata have solutions to effectively address the issues of the track deformations and ingress of the ballast into the blanket layers. Strata products can address these issues very effectively and are very easy to install. Once installed, the stability of the track will be much better. The geosynthetics technology will help in confining the ballast and the sub-ballast layers and will restrict movement of the material.

What are the global practices in using such products and solutions in railways?

The US and many parts of Europe or other developed nations have already built their infrastructure in the 60s and 70s, and there are no new constructions happening. Geosynthetic industry has evolved only in the last 50 years. So, a lot of the older construction in these nations did not use geosynthetics. Newer constructions in the last 20 years are taking place in very few countries. China was one of the largest countries, they used geosynthetics in their high-speed bullet trains. Russia built kilometres of railway tracks using geosynthetics. All countries where new construction was taking place have a very high level of adoption for geosynthetics technology. The only thing is how do we take the success and adoption from one sector to the other sectors. Highways has a very high degree of adoption now. How to replicate this success to the other sectors, must be explored.

How is the adoption of geosynthetics solutions in railways sector?

Railway network is evolving and being upgraded. Currently most of logistic is still through roadways.

Roads are the most expensive form of transportation while railway is cheaper as compared. We already have a very strong train network. Why don’t we strengthen that and make it faster? Clearly there is a demand-supply mismatch. The government has recognized the needs and started a lot of developments and modernisations in the railway network. Now there will be a lot of projects, money being spent in doubling and quadrupling of railway tracks with dedicate freight corridors. The highway sector went from 2-lanes to 4-lanes and 6-lanes and now we are talking of 8 lane expressways. Railways also needs to follow this trend.

Many dedicated freight corridors have been started recently. Were your solutions been used in these projects?

The Dedicated Freight Corridor Corporation (DFCC) has adopted some solutions for corridor projects, such as using our StrataWeb® geocells for transition slabs. In the Western Corridor project, they are using our geocells as a transition zone and for embankment slope protection.

DFCC has provided guidelines, and the Railway Board has approved them. The goal is that for any new bridge being built in the railways, our solutions will be used in the bridge approaches. This is what we are trying to promote across the network.

What are the other key solutions from the company?

One of the biggest problems faced by the construction industry during the rainy season is the disruption caused to construction, road maintenance, and track maintenance. While rainfall is essential, it can lead to flooding and water accumulation, weakening the subgrade if proper drainage is not provided. To tackle this effectively, we offer a solution using StrataDrain™ drainage composite. This polymeric drainage roll provides drainage performance comparable to that of a nearly one-meter-thick stone layer.

Traditionally, drainage systems have relied on layers of stones, allowing water to flow through the gaps. However, the cost of stone has risen significantly due to the increasing expense of quarrying and transportation in many regions. StrataDrain™ offers a cost-effective alternative with a polymeric drainage layer that is approved by the Research Designs and Standards Organisation (RDSO).

Geosynthetics aim to replace natural materials with synthetic, factory-made engineered products that deliver the same functionality at a lower cost and for a longer duration. Unlike natural materials, polymers do not degrade, making them a reliable and long-lasting solution for drainage.

Which are the projects you are working on in railways?

In the Dedicated Freight Corridor Corporation (DFCC) projects, we have successfully supplied geosynthetic products to Tata Projects and L&T. Currently, these products are being actively utilized in the Western Zone, where they have now started specifying them for upcoming bridge projects, whether for upgrading existing bridges or constructing new ones. Our aim is to expand our reach across all zones by raising awareness and promoting the benefits, ensuring their adoption in projects nationwide.

What are your growth plans?

We anticipate growth beyond highways sector into railways, water management and industrial areas. Our focus is to leverage on the growth of these sectors. Our objective is to provide long term and sustainable solutions with the help of the spectrum of our products.